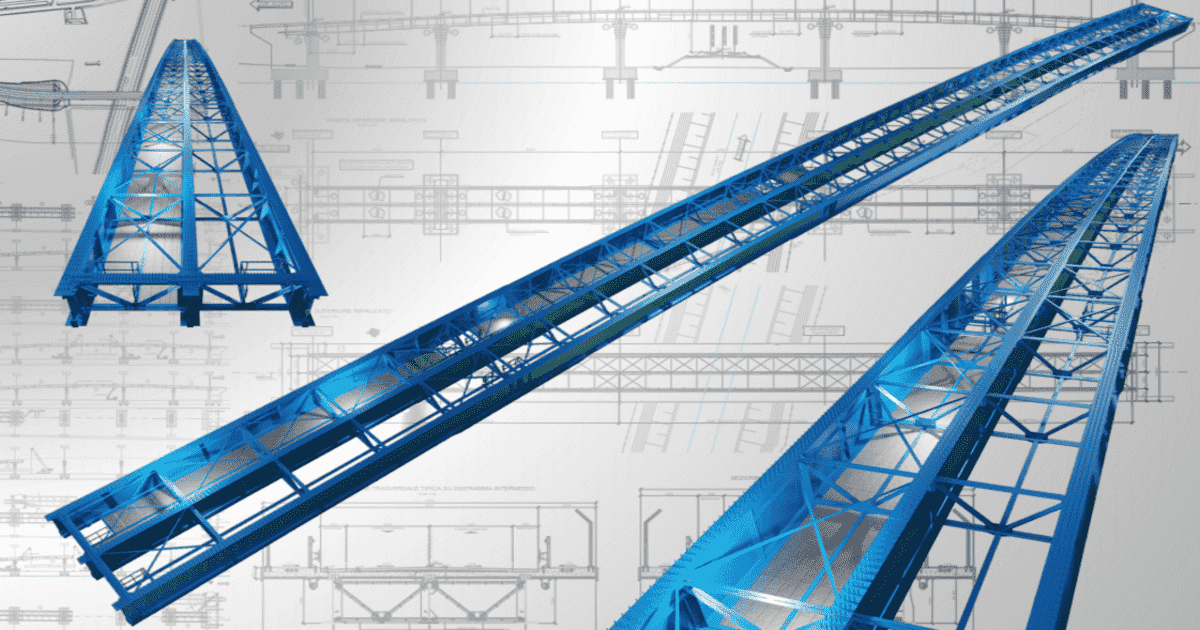

IV05 Railway Overpass - Verona/Padua high-speed rail line

As part of the High Speed/High Capacity railway project Verona-Padua Sub section Verona-Vicenza, 1st Sub Lot Verona-Montebello Vicentino, LMSteel Consulting was in charge of the "design for manufacturing" construction service of the IV05 railway overpass at km 14+674.36 for a total of 450 tons of metal carpentry.

The railway overpass in question has an overall length of 160 m and is characterized by the succession of five spans of spans of 25, 35, 40, 35, 25m respectively. The deck, with a total width of 13.00m, is characterized by a paved part affected by the roadway, 8.50m wide, and two 2.25m side curbs. The deck is completed by the finishes, the flooring, the prefabricated veils, the safety barriers and the protective nets.

The metal structure is made up of 3 main metal beams placed at a distance of 3.75 m with a constant height of 2.00 m made with welded composite double T steel profiles. The main beams are connected by reticular diaphragms placed at a maximum distance between centers of 5.0 m. Between two successive diaphragms there are transverse stiffeners placed at most every 2.50 m. The bond between the metal deck and the substructures is achieved through the use of elastomeric isolators.

The substructures are traditional. In particular, the piles have a shaft with a full pseudo-rectangular section profile, with rounded edges, inscribed in a rectangle with plan dimensions of 7.60mx1.50m. In the top part of the pile, for a height of 3.70m, the shaft is flared to create the useful surface for housing the baggage at the top, characterized by a pseudo-rectangular section with external dimensions of 10.90mx2.30m.

The concrete deck slab, with a constant thickness of 30 cm, is cast on prefabricated concrete platforms with a thickness of 7 cm which act as formwork for the casting. After the casting has cured, the deck slab, connected to the beams using Nelson-type connectors, collaborates in a longitudinal direction with the main beams.

Transversal seismic restraints are arranged between the beams, both on the abutment and on the pier, while longitudinal seismic restraints are present only on the abutment, in the rear beam.

LMSteel Consulting provided construction engineering services following the RFI project specifications and supporting the General Designer in the study of the Launch Phases.

The project was developed by creating the numerical models of the temporary structures with SAP2000 and the 3D BIM LOD G geometric models with Tekla Structures.

More information on the project at the following link:

- PLACE

- Verona-Montebello Vicentino (Italy)

- YEAR

- 2023

- StatE

- Completed

- ServiCES

- 3D BIM Modelling - Design for Manufacturing

- workshop-drawings and as-built

- Launching Phase assistance

- FINAL CLIENT

- RFI

- General Contractor

- Consorzio IRICAV 2 – Cossi Costruzioni spa (Webuild group)

- STEEL MANUFACTURER

- LMV spa

- DESIGN TEAM

- RFI

- WEIGHT [TON]

- 450

Project Photo Gallery IV05 Railway Overpass