Special projects

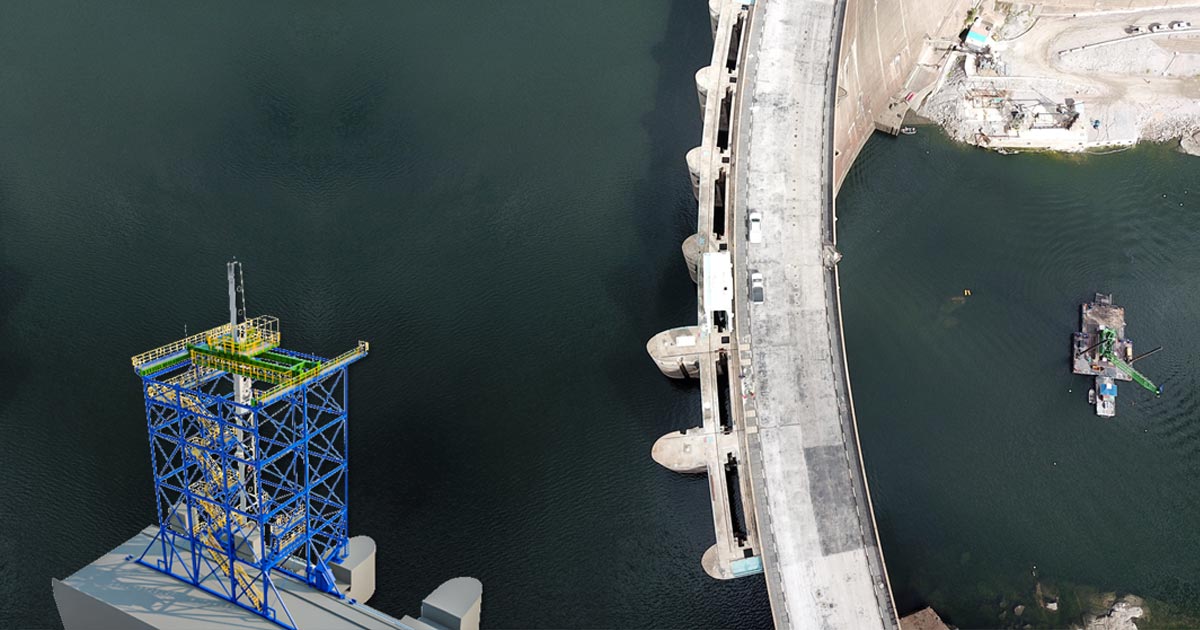

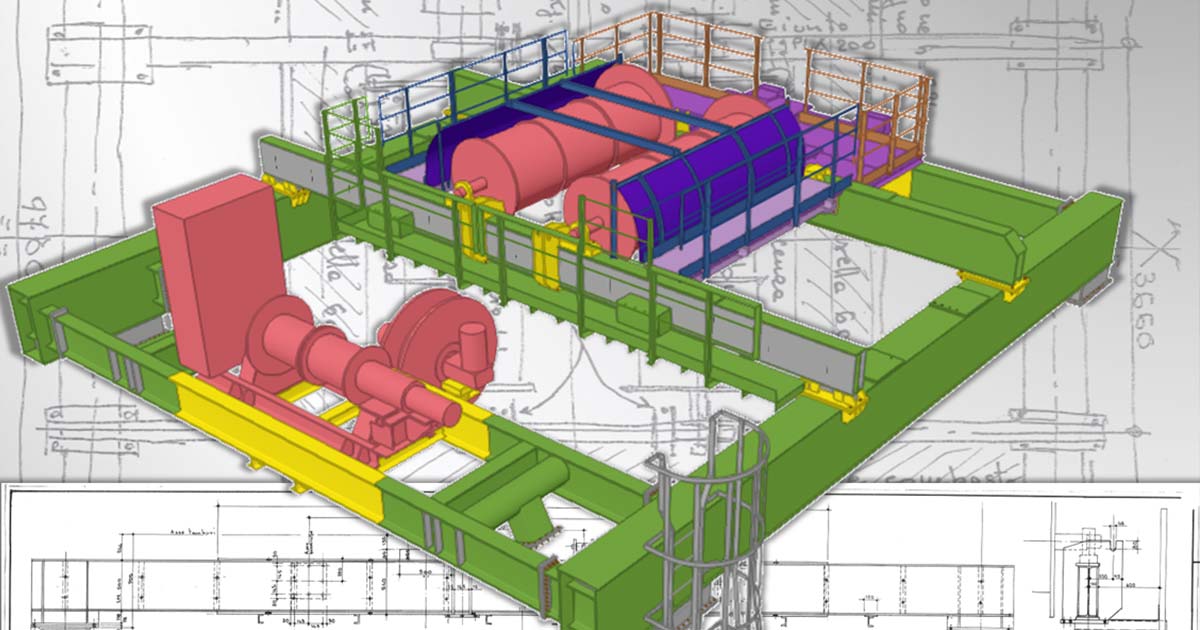

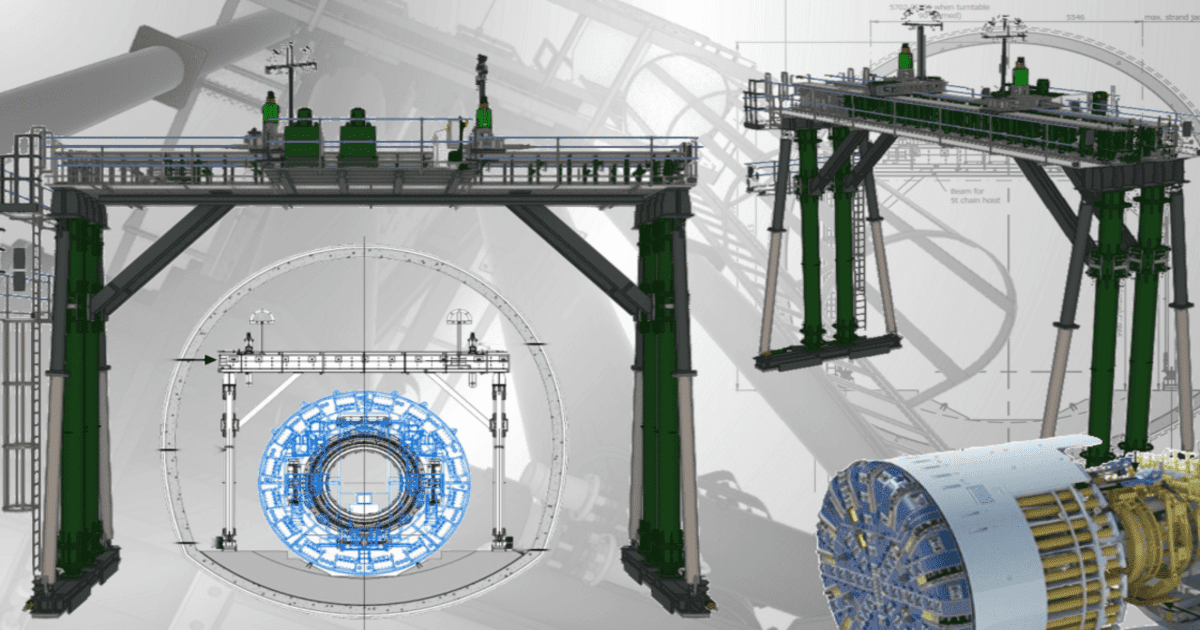

Civil and mechanical structural design for the construction of support structures for kinematic mechanisms and winches, gantry cranes, handling and lifting equipment by means of hydraulic pistons, sliding on Teflon rails and slides, specific engineering at the request of the customer. Local numerical analysis for tension verification of welded and bolted joints, sling bars and eyebolts. Verifications according to Eurocodes and FEM Directive.

Lifting and handling equipment

With the experience gained in the design of large works, we are also attentive to the conception of the assembly and construction site phases. We aim to provide solutions that are truly compatible with the conditions of the site. To pursue this goal, we establish fruitful collaborations with producers of overhead cranes, winches, and gantry cranes to devise together the best technical-economic solution that meets the expectations of the Clients. Thanks to the collaboration with technicians in the sector, we also provide risk analysis services, assembly diagrams also for the electrical / mechanical / hydraulic parts and use and maintenance manual.

Lifting and handling equipment

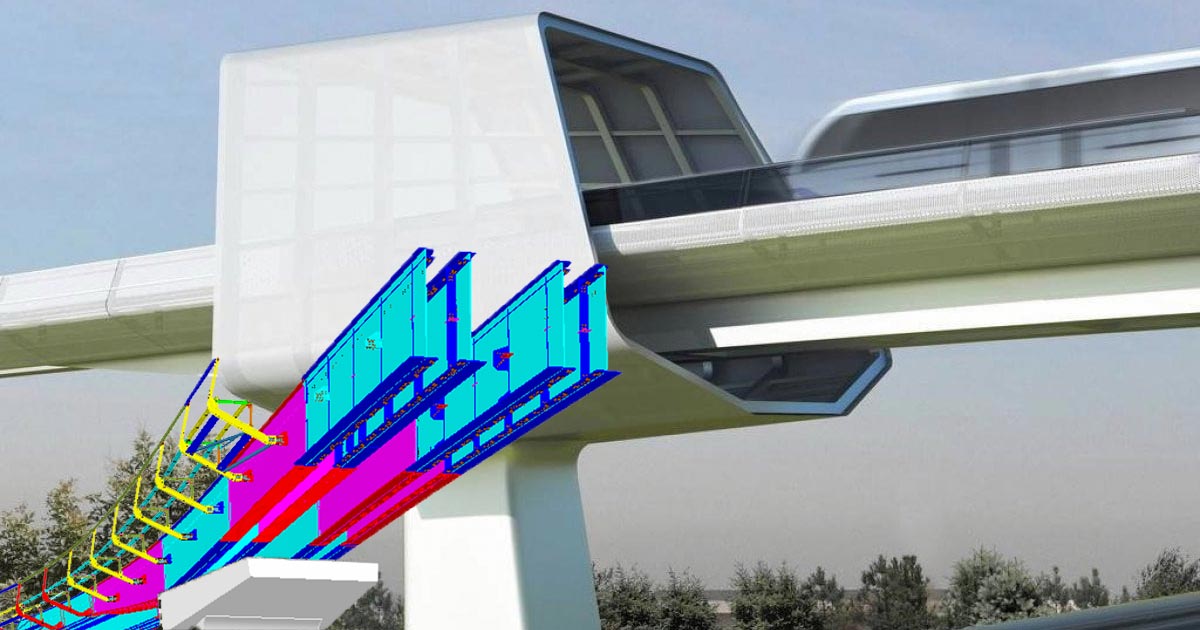

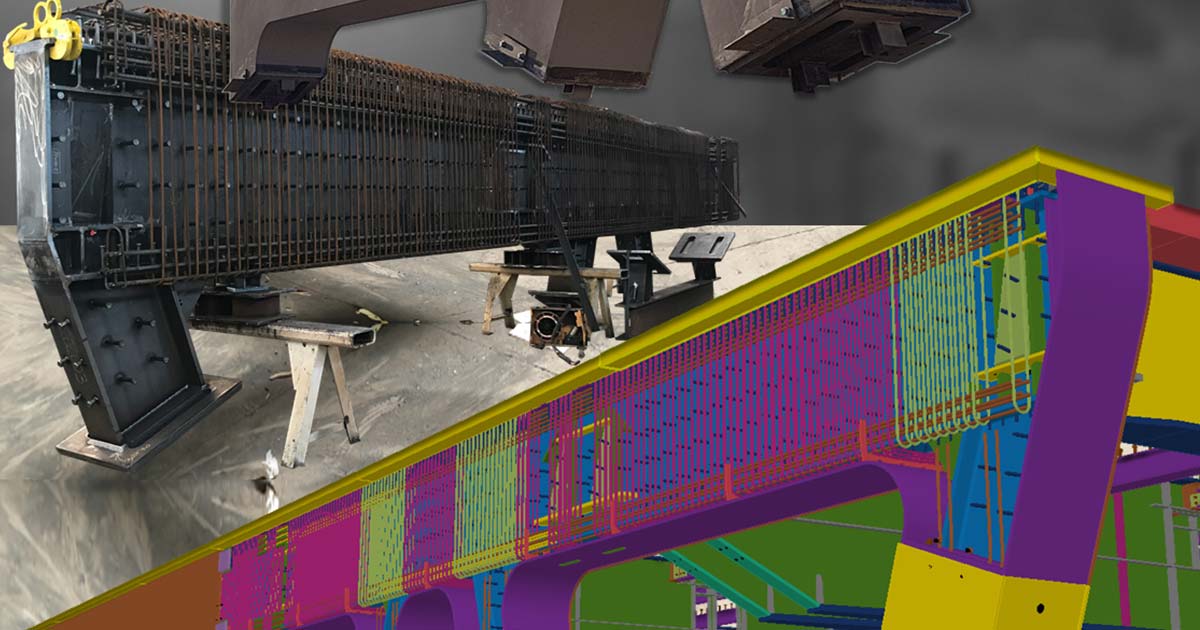

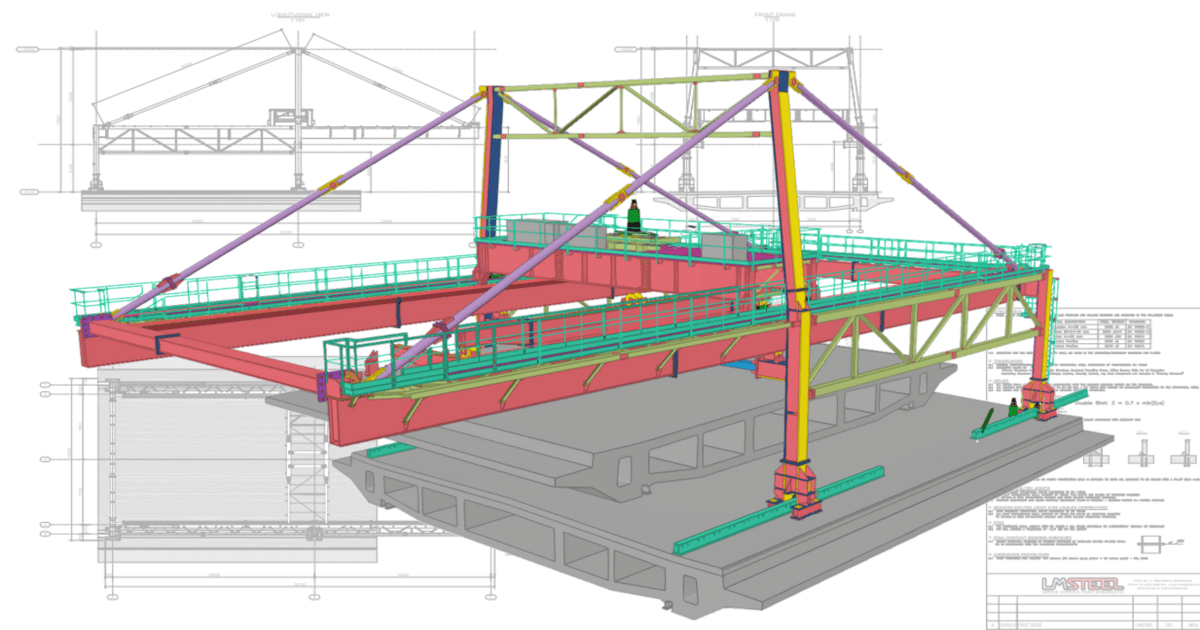

Launch projects

The launching operation of a deck consists in setting up the infrastructure by lifting from below, front launching by pushing, launching with cantilevered advancing segments or various special ones. The launching method influences various structural aspects, such as the type of section and the construction details and is also done by analysing the conditions of the environmental context, such as the possibility of having a launching field for the launch of the segments, or the positioning of the self-cranes inside the riverbed. These aspects are analysed during the preliminary coordination meetings with the clients following which the best possible solution compatible with the characteristics of the building is proposed. A preparatory BIM model is created for the study of the launching and construction phases of the works. The necessary equipment is designed, such as gates and temporary towers for altimetric alignment, and temporary lifting and pushing structures. The consultancy service includes the study of the structure during the transitional period, how the bending stress changes when the segment passes through a section of span and pile, or the concentrated action of sliding on sleds or trolley racks, and the need to integrate the structure with any temporary stiffeners.

Launch projects

Fatigue design of cranes and overhead traveling cranes

We have worked for several years in a steel plant providing consultancy on the structural design of lifting equipment and runways for bridge cranes. We design the structures according to the UNI EN 1193-6: 2008-09 standard, analysing all aspects of actions on the flange and weld seams and considering the fatigue analysis according to the imposed work cycles. In the case of existing beams, we verify the need to add stiffeners or beams for torsional stability in the case of commissioning of overhead cranes with greater capacities, considering the buckling checks of the core panels. Information about buffers and fixing clips are studied together with the Client based on the products available on the market. We are familiar with the Machinery Directive 2006/42 / EC and the harmonized standards UNI EN 13001 which cover both general aspects concerning the structural calculation of lifting appliances and specific aspects of the various constituent elements, such as, for example, the calculation of ropes, cylinders hydraulic systems, wheel-rail contact, etc.

Consult us for specific advice also for the evaluation of the functioning of existing equipment.

Fatigue design of cranes and overhead traveling cranes

Support structures for storage silos, conveyor belts, pipe racks lines

Drafting of complete lay outs for production lines together with the study, design, and adaptation of customized machines in existing systems, revision, adaptation, and capacity increase of existing machines (e.g., modular filters, etc.), research, consultancy on existing plants to improve their efficiency (e.g., energy saving, reduction of maintenance costs, reduction of plant shutdowns, etc.), problem solving. Projects developed in 3D BIM models complete with bearing structures, belts, winches, conveyors, for the control of interference and vision of the production process.

Support structures for storage silos, conveyor belts, pipe racks lines