Kariba dam Hydroelectric dam

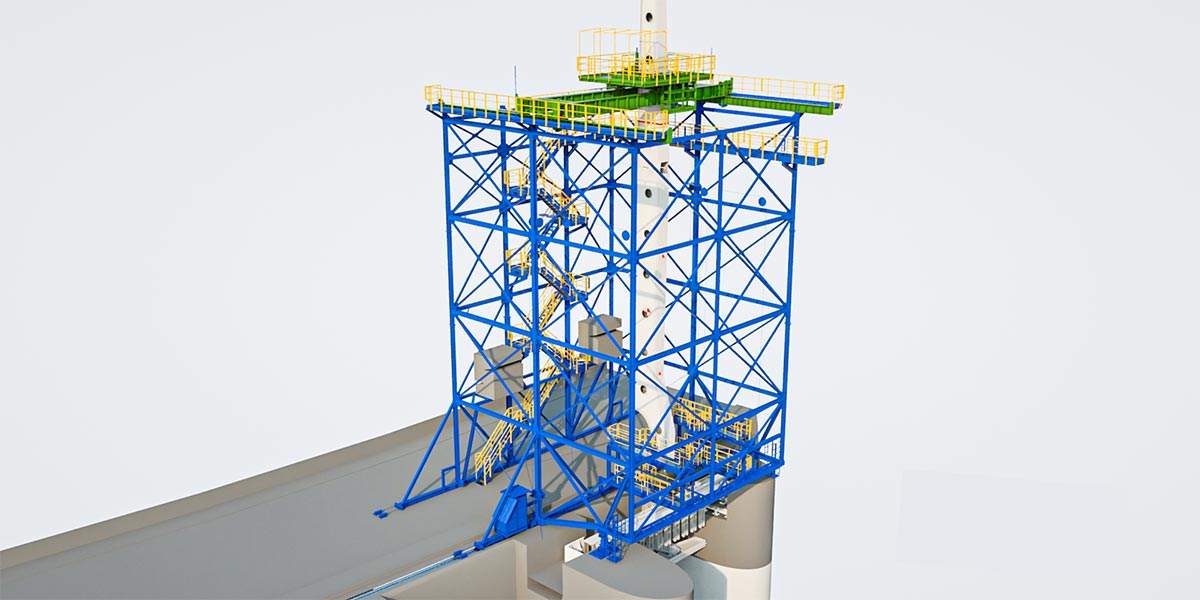

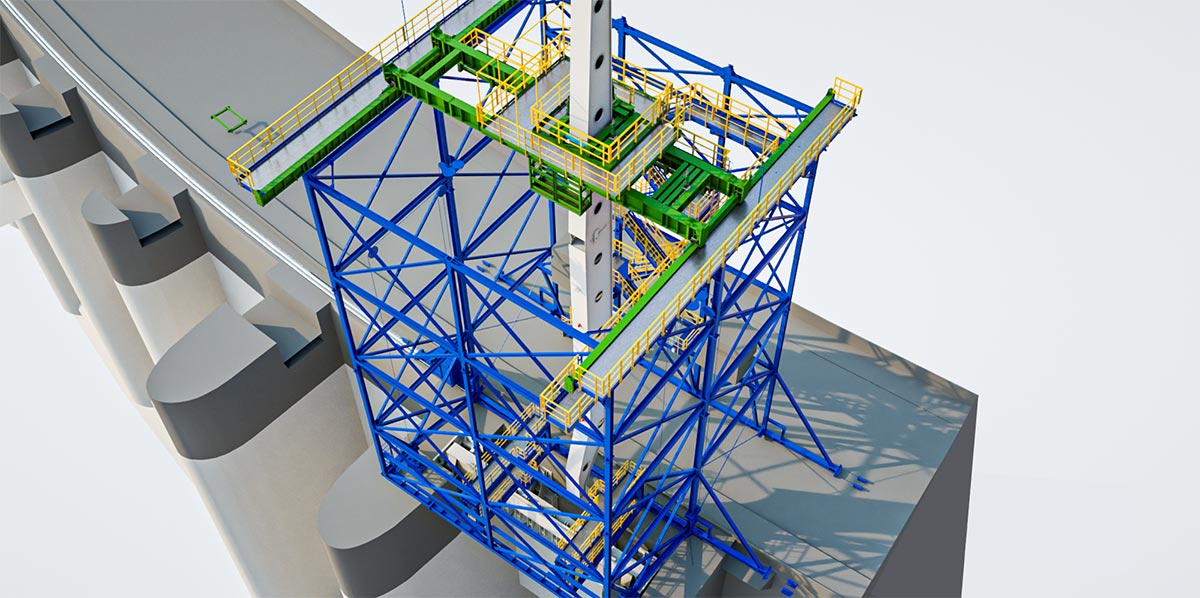

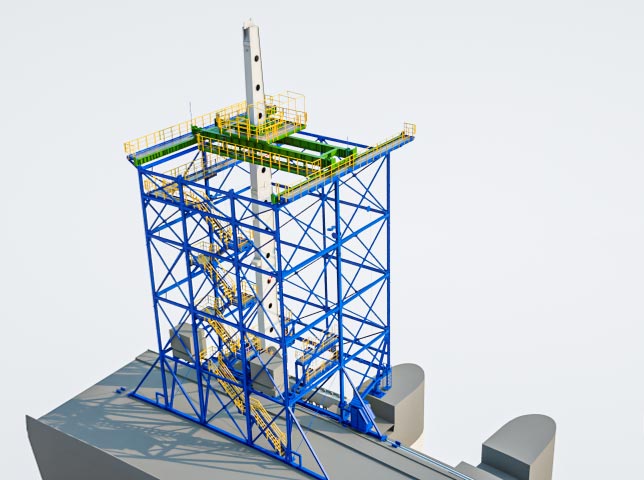

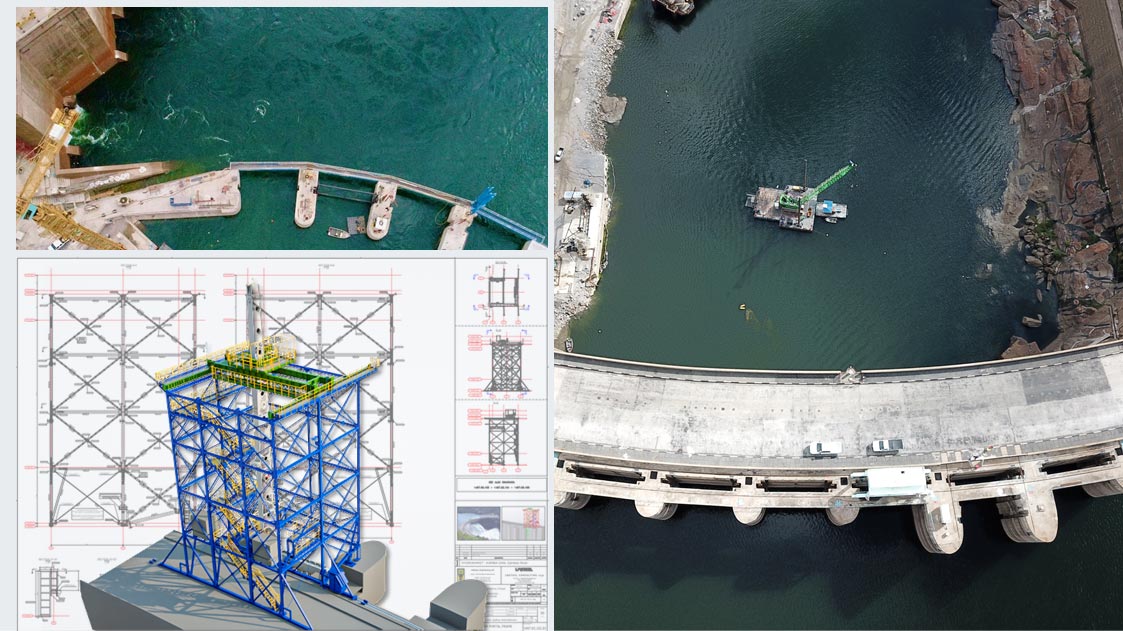

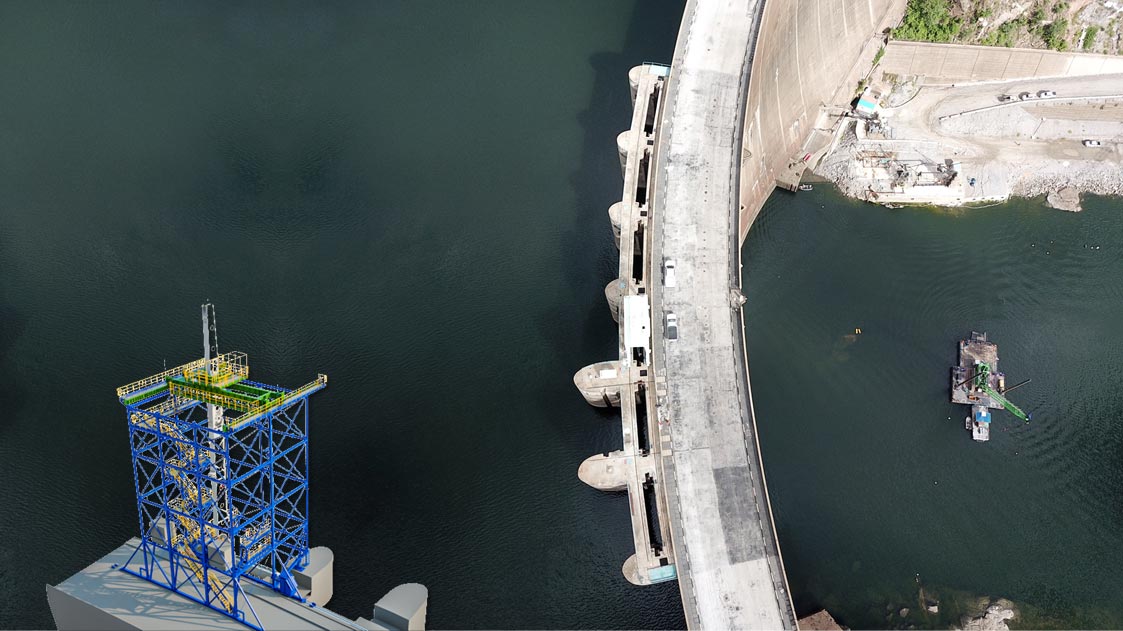

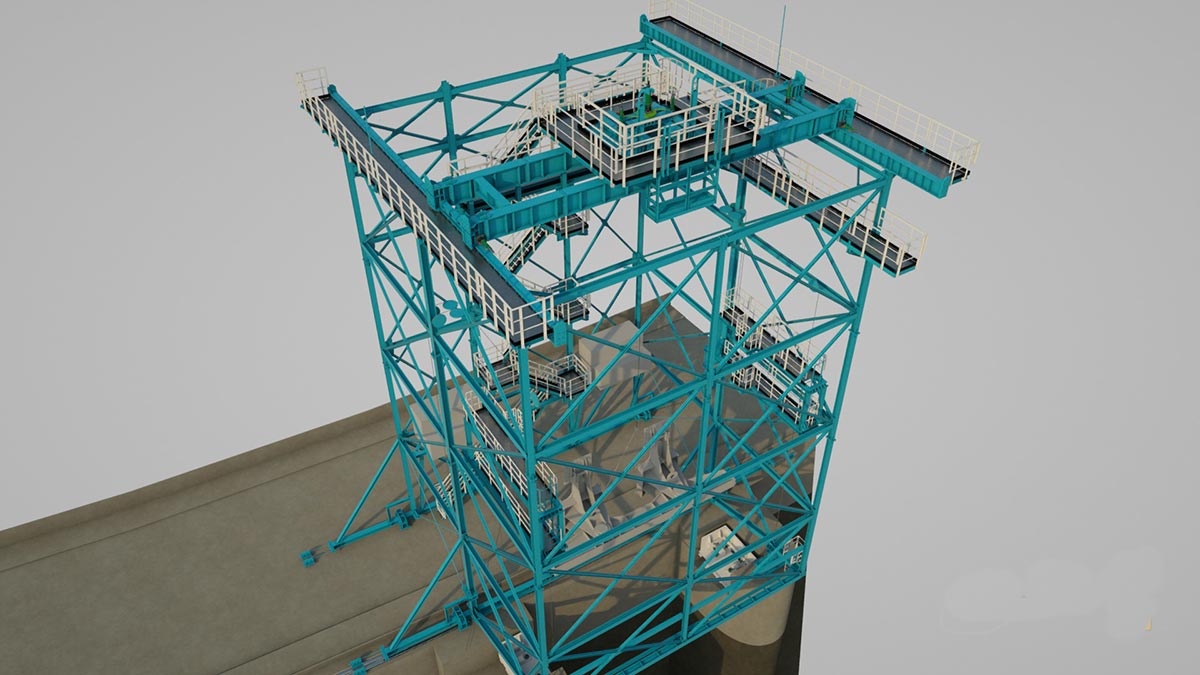

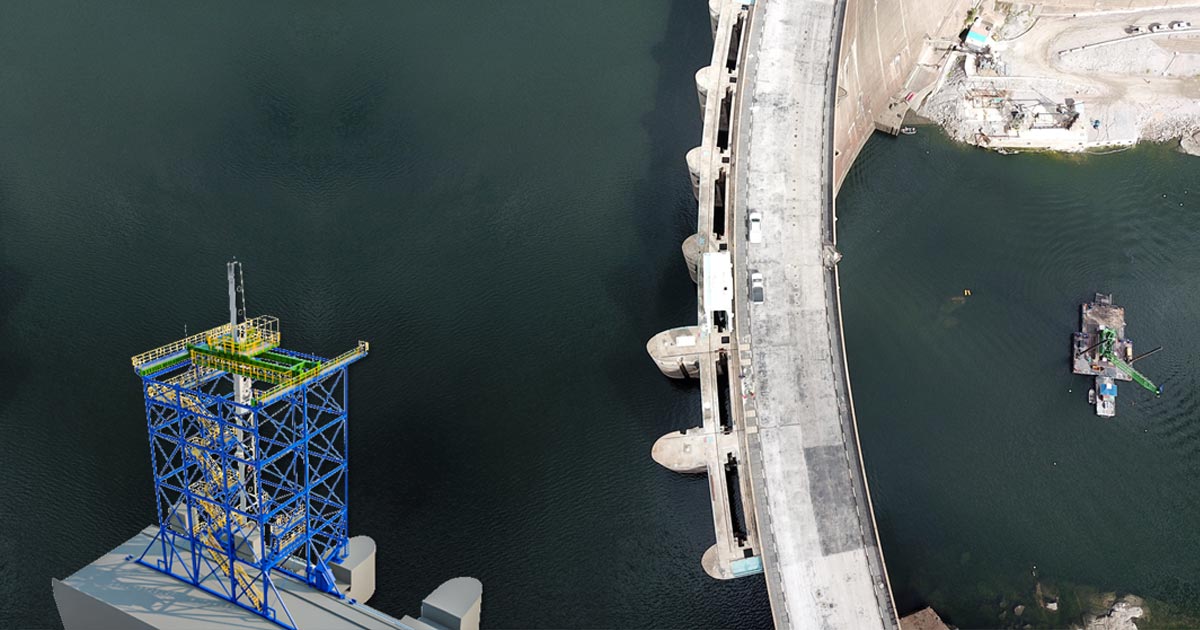

spillway refurbishment - NEEDLE COFFERDAM PORTAL FRAME

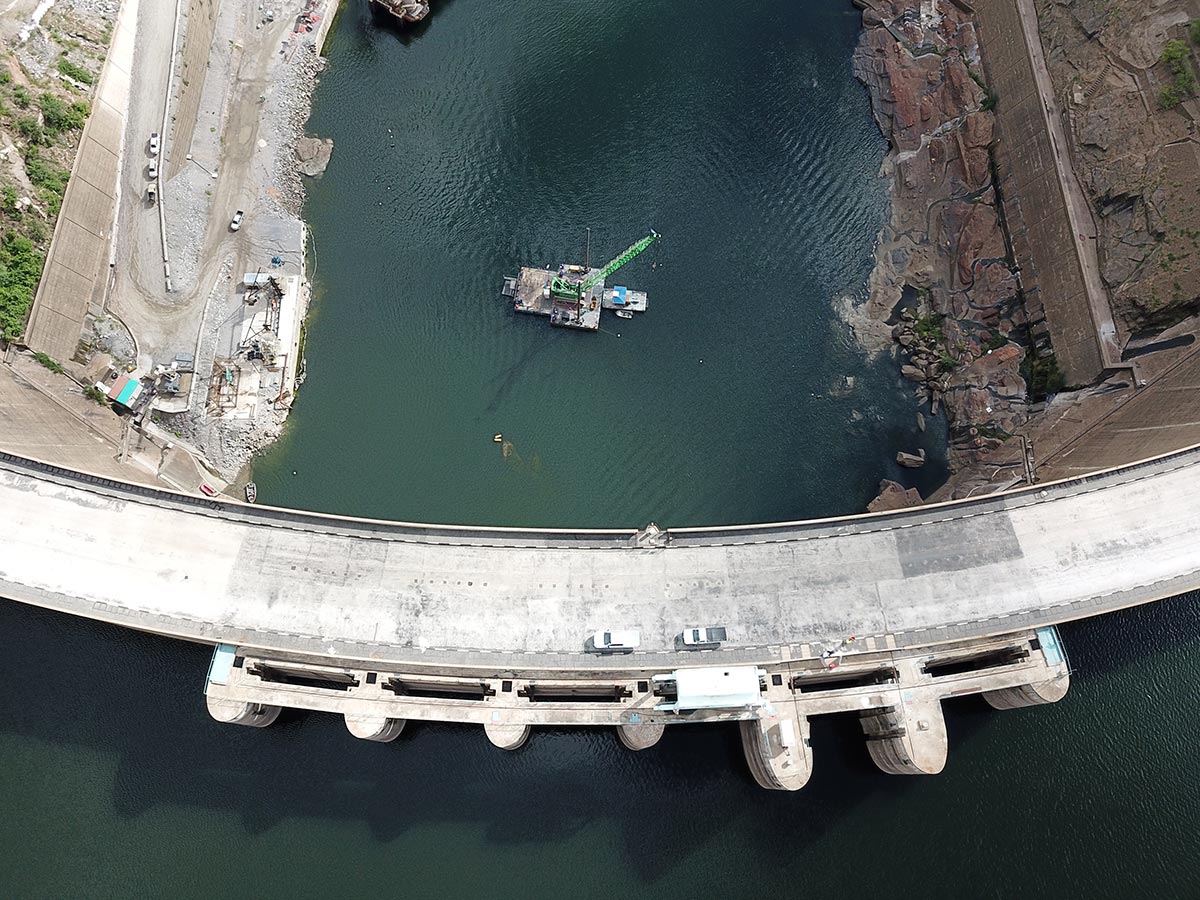

GE Hydro France and Freyssinet International have until 2023 to complete the rehabilitation of the Kariba hydroelectric dam spillway. The two partners have already started installing the equipment on the project site and it is expected to continue gradually over the next 10 months. The spillway for this water retention consists of six sluice gates located at the top of the concrete wall of the dam. From these valves the water is discharged into the immersion basin to manage the water levels in the tank. This project is now on track, although at the height of the 2019 rainy season, the level of Lake Kariba was only 5m above the minimum operational level instead of the usual 8m it reaches at this time of year. This situation logically leads to a decrease in electricity production. The production capacity of the hydroelectric plant (1,626 MW) attached to this dam has already decreased by around 600 MW. The situation could worsen in the coming years if water retention is not restored to its original state. The rehabilitation of the Kariba Hydroelectric Dam will require a total investment of $294 million. Funding is provided by the ZRA through equity and loans from the World Bank, the African Development Bank (AfDB) and the European Union. The mission entrusted to LMSteel Consulting sagl consists of the executive and construction design of the steel support structure and movement of the large steel ashlars (needles) necessary for the rehabilitation of the works along the 6 gates of the dam. Thanks to the deep knowledge of HEBETEC Engineering AG, a leading Swiss company in the field of large lifts, we have designed a product capable of lifting blocks weighing 40 tons and able to move on Teflon supports suitably sized along the radius of curvature of the dam. This for the entire duration of the works estimated at 36 months. The structure, weighing 200 tons with a height of 27 m, is designed to withstand the pressure of the winds, which in that area reach gusts of 30 km/h (200 kg/m2). The logistics of carrying out the production in Europe forced us to conceive the modular structure and with dimensions such as to be confined in a total of 10 containers for sea shipment. In the movement sequences we had to consider the simultaneous presence of vehicular traffic, considering that it is the main artery linking Zambia and Zimbabwe. The technology supplied by Hebetec Engineering AG makes it possible to automatically perform the unloading from the truck and the handling in the needle in sequence with only the maneuverer using hydraulic jacks.

- PLACE

- Zambia

- YEAR

- 2020

- StatE

- In progress

- ServiCES

- Progettazione Strutturale Esecutiva Portal Frame, Assistenza alla progettazione delle parti idrauliche, slitte di movimentazione e funi di tiraggio, Modellazione 3D BIM - Design for Manufacturing | Piano di Varo e verifica sequenze di movimentazione, Construction Management, Piani di officina, progetto montaggio, as-built

- final CUSTOMER

- GE - General Eletric Hydro France / Freyssint Internation (Vinci Construction)

- EPC Contractor

- Hydrokarst Groupe | Hebetec Engineering AG

- MetalWORKER

- LMV spa

- ENGINEER

- Stucky - Gruner ag

- WEIGHT [ton]

- 220

- Portata [Ton]

- 40

Kariba dam Hydroelectric dam