Floating Transfer Station

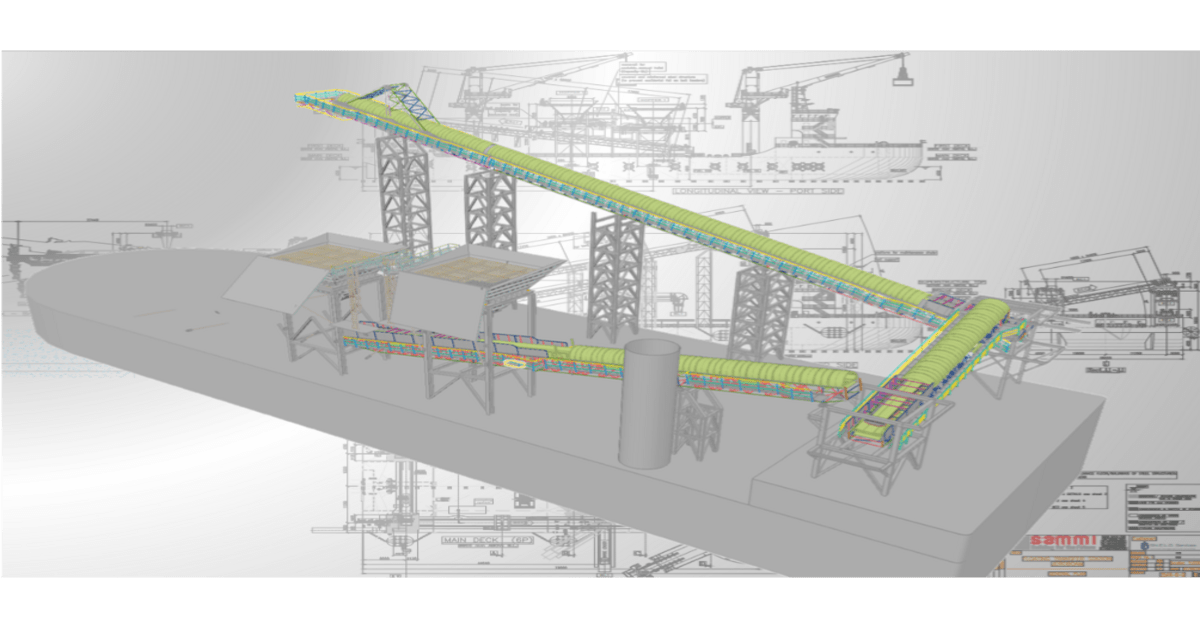

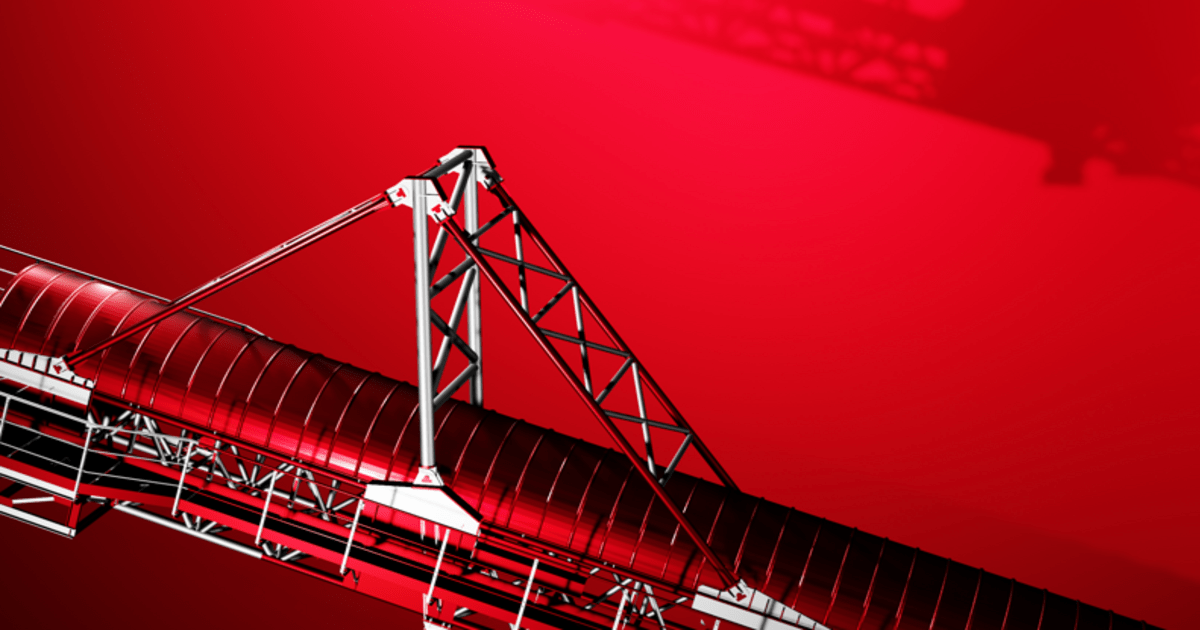

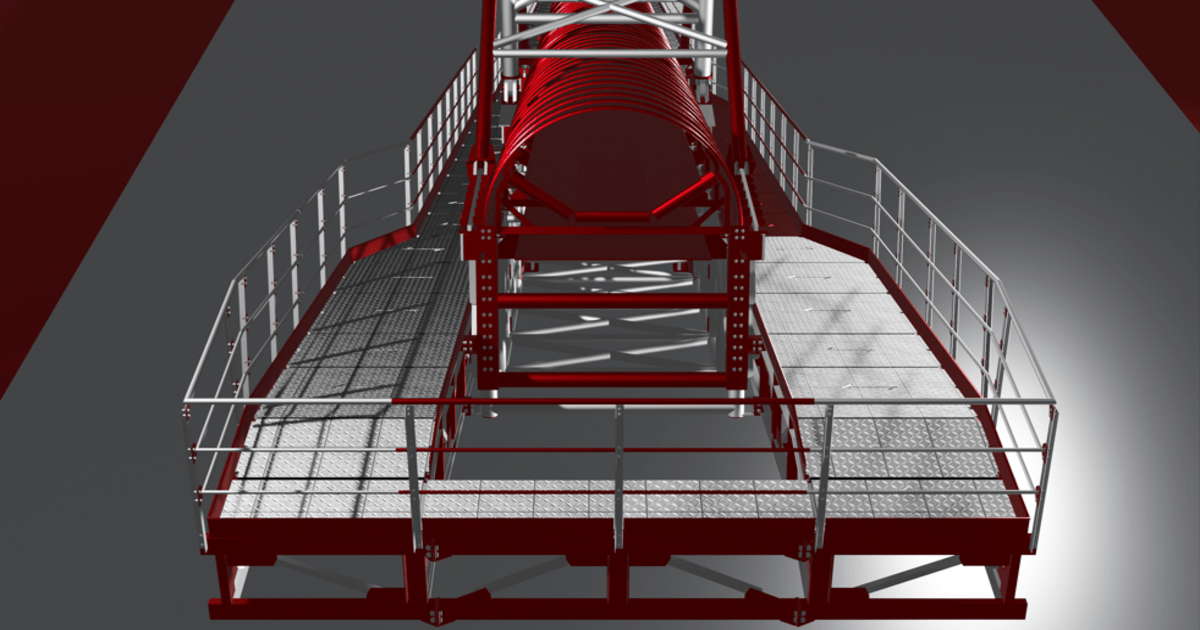

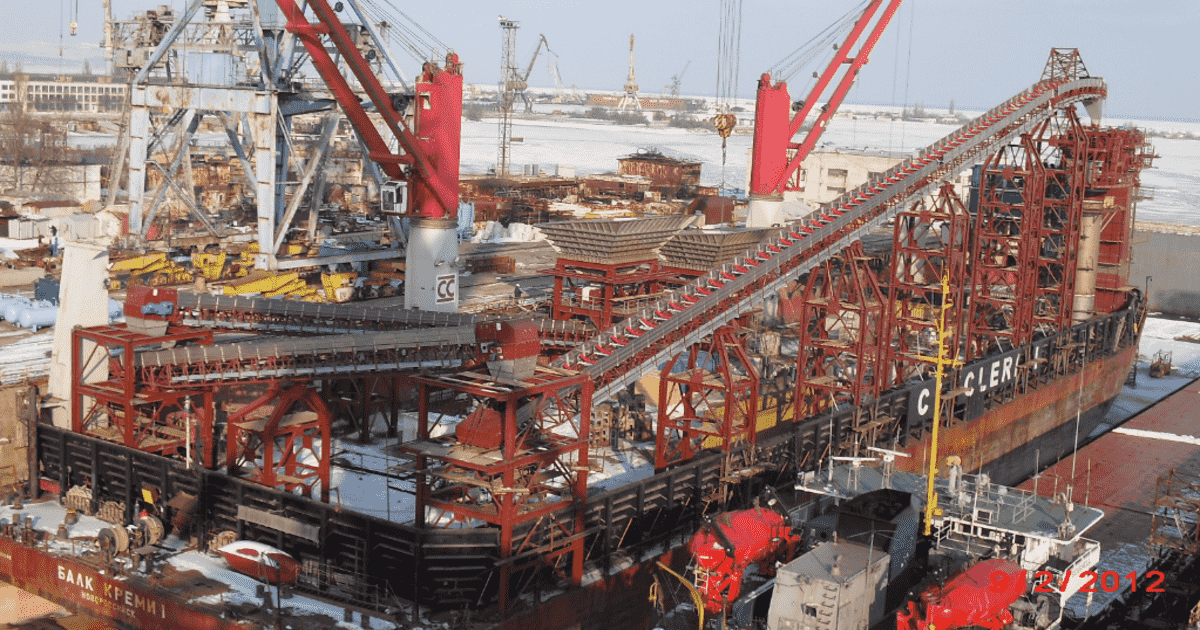

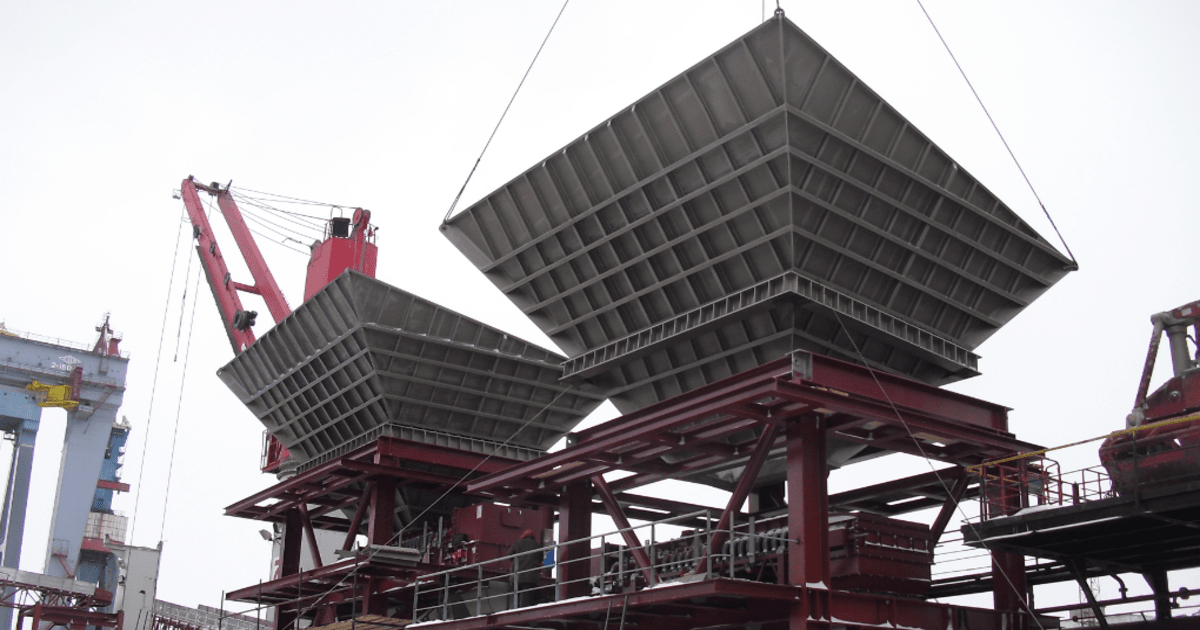

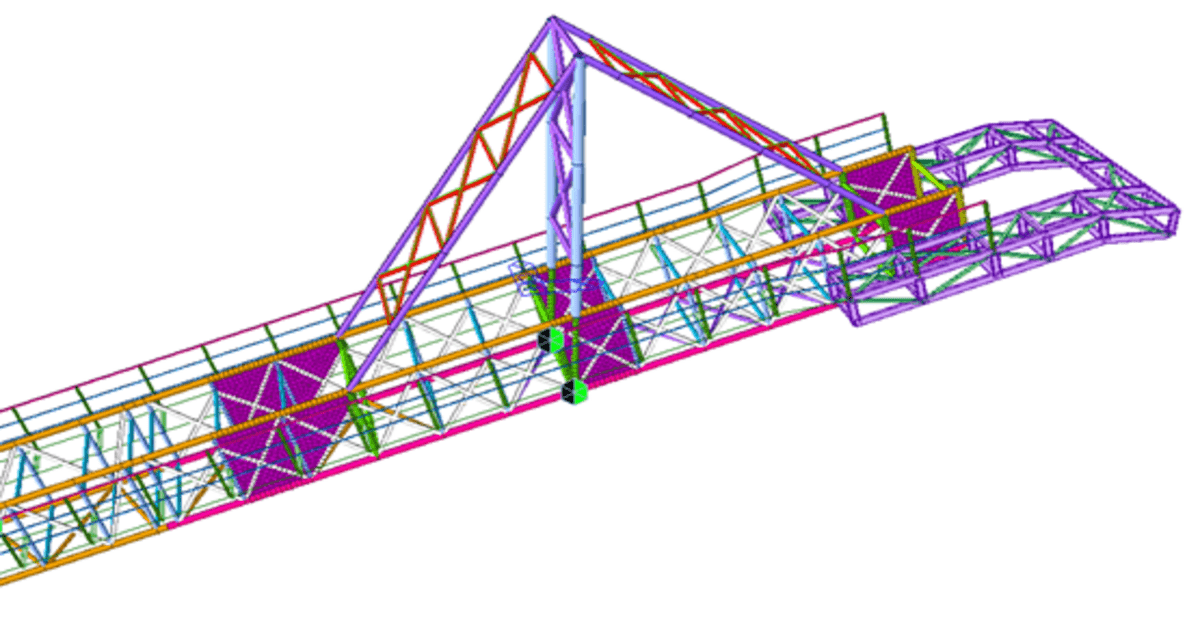

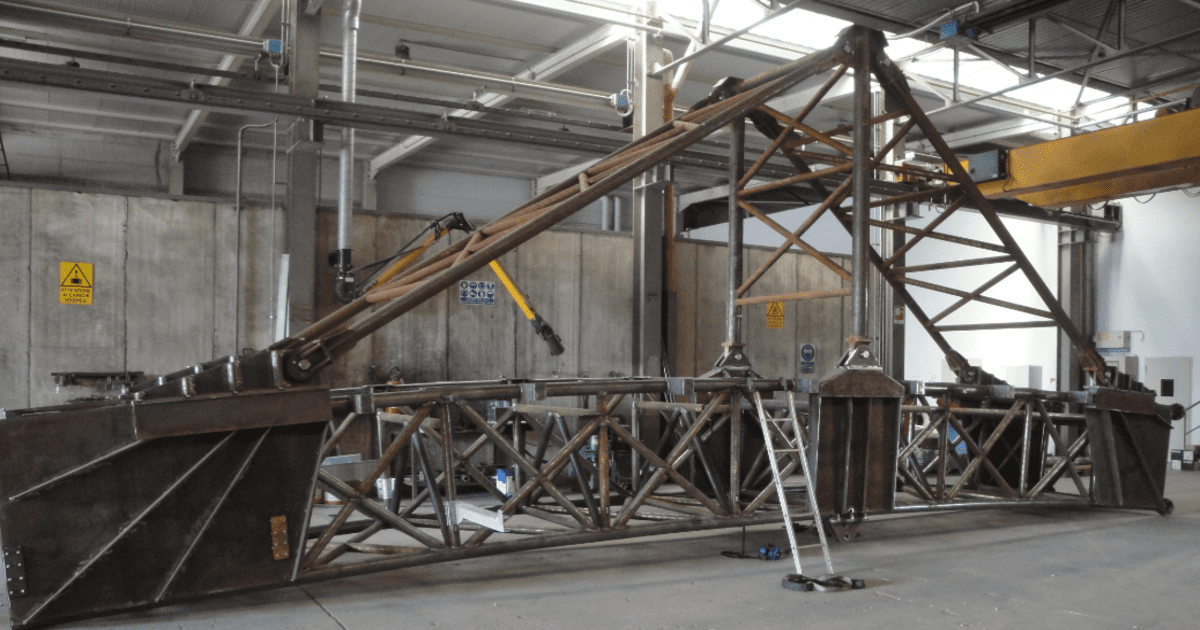

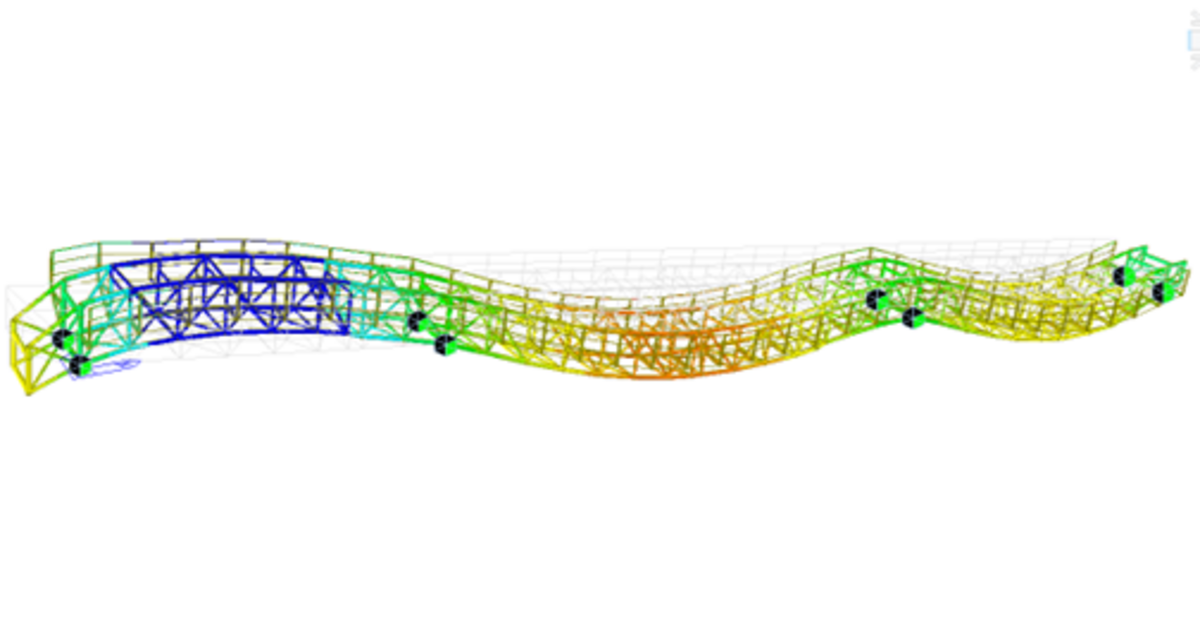

The Off-shore FTS (Floating Transfer Station) system allows the transfer of bulk material (Manganese) with 2 Grab Cranes which feed the receiving Hoppers located on the lateral side of the specially set up vessel. Through the extractor belts the material is conveyed through a path formed by n°3 belts conveyors which will transfer the same to a ShipLoader on the starboard side of the FTS. Operation of the transport system is carried out from a control room, located on the bridge deck. The electrical and control cabinets required for the operation of the conveyor system are installed in an electrical room, positioned at the level of the main deck close to the deck superstructure. The design flow rate of the handling system described above is 2,500 T/h of manganese, iron and bauxite, and 2,000 T/h of coal.

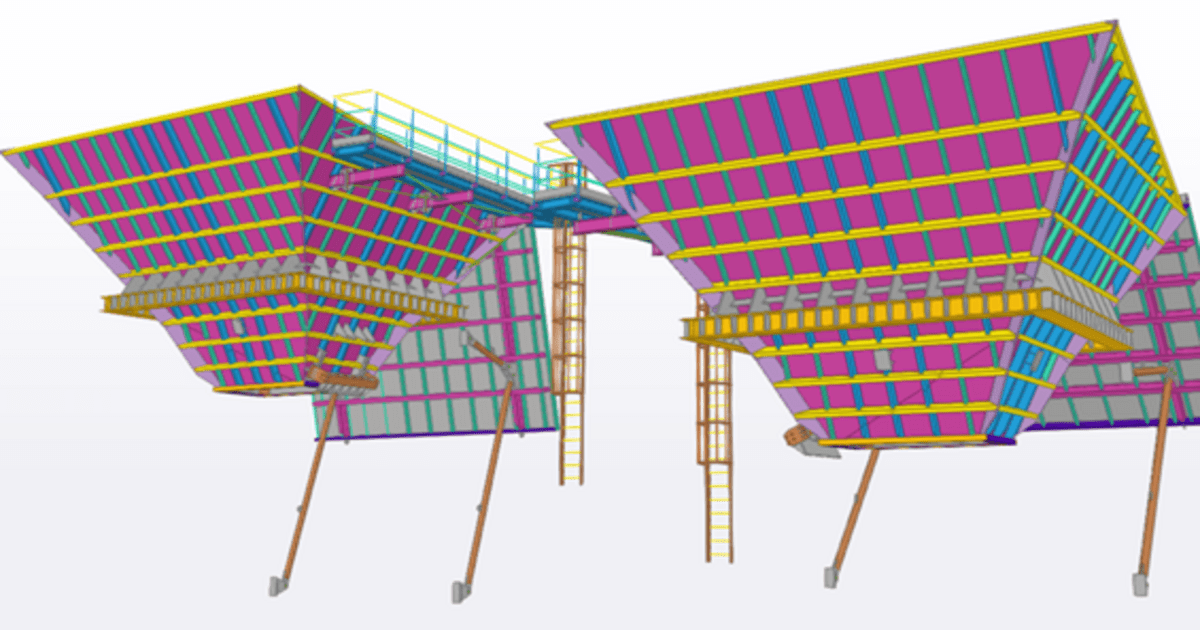

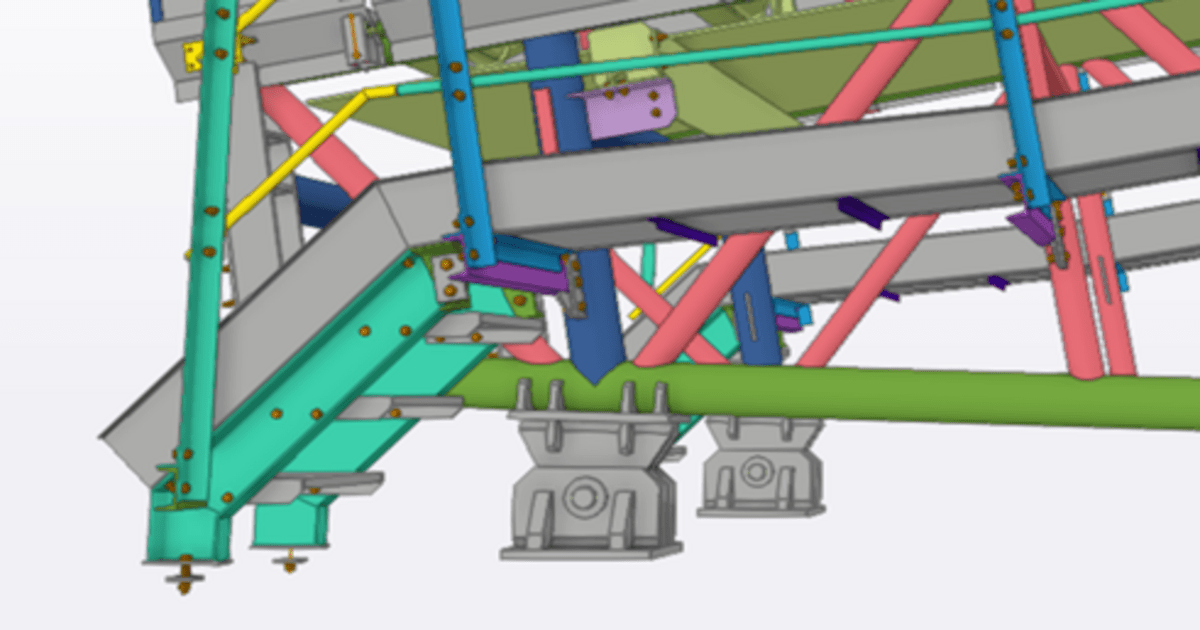

LMSTEEL Consulting sagl has been selected as Principal Design Engineer for the following activitiesr: Steel Structural Design (Basic and detail), BIM modeling "design for manufacturing" and workshop drawings of the 3 belt conveyors and the 2 Hoppers and related mechanical components.

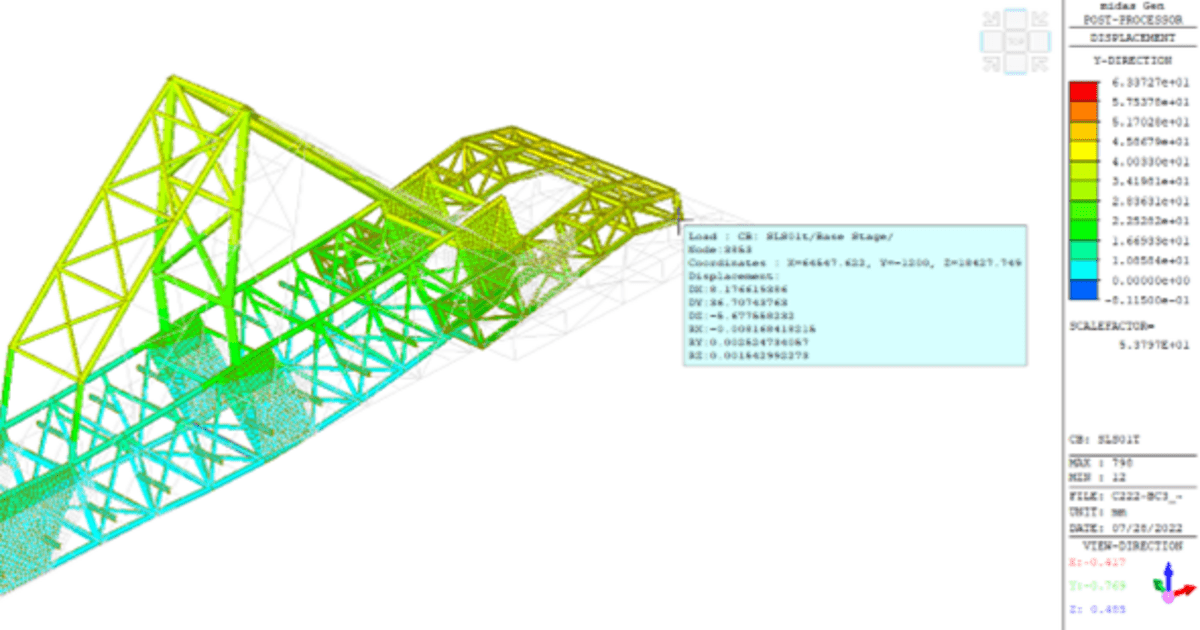

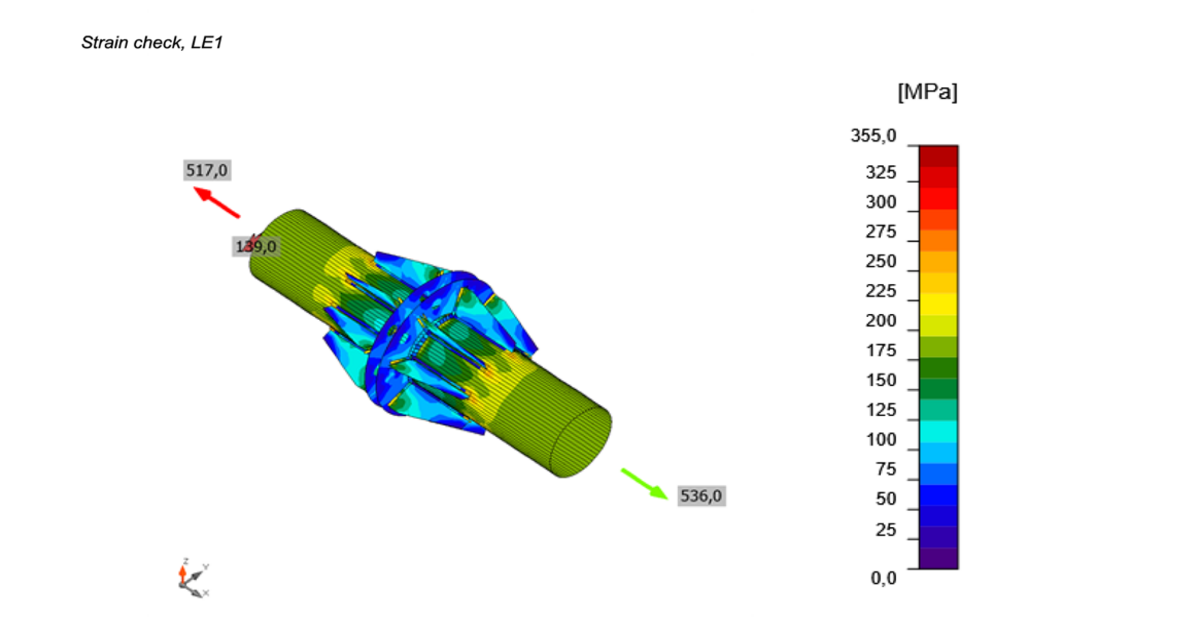

Among the conditions of analysis of the structural design there were the considerations given by the accelerations of the ship in operating condition.

The project was developed by creating numerical models with Midas Gen and geometric models with Tekla Structures.

- LOCATION

- Off-shore

- YEAR

- 2022

- StatE

- Completed

- SerVICES

- Structural Design (Basic & Detail)

- GA Drawing

3D BIM Modelling - Design for Manufacturing

workshop-drawings and as-built - FINAL CLIENT

- Confidential

- General Contractor

- Confidentia

- STEEL MANUFACTURER

- SAMMI srl

- ENGINEER

- LMSTEEL Consulting

- WEIGHT [ton]

- 300

Project Gallery Floating Transfer Station