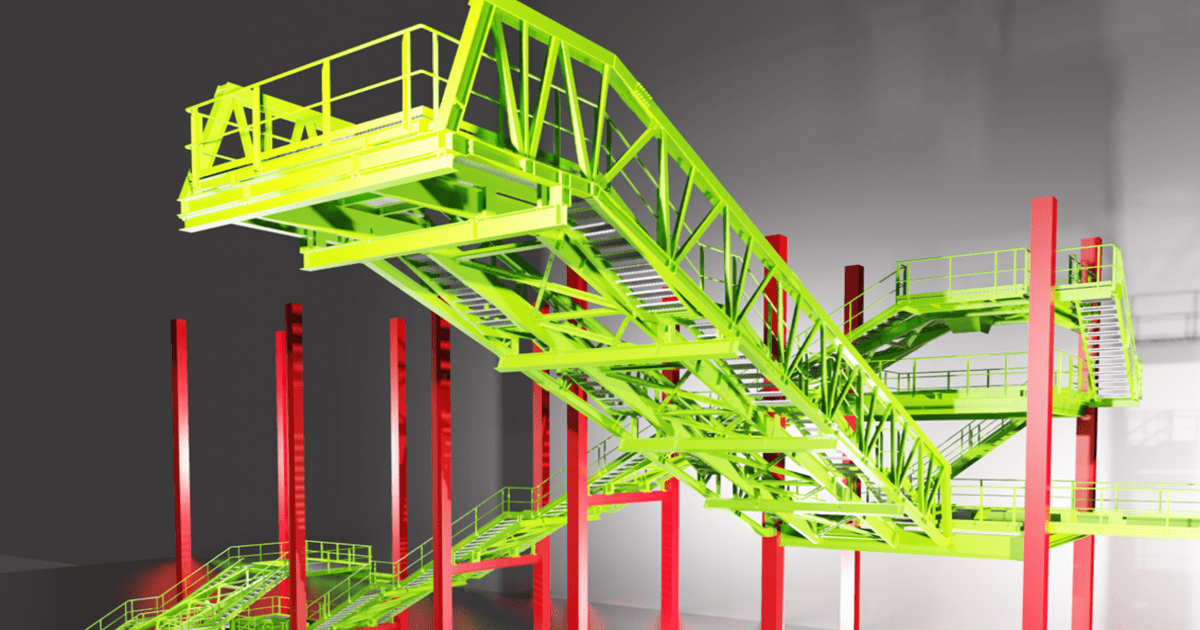

Hot Shredded Scrap Handling System

The aluminum scrap used as raw material comes from various sources, and the presence of impurities requires preliminary treatments (sorting, shredding and heat treatments) in order to improve the quality of the scrap in terms of metallic yield and recyclability. Aluminum slagging operations typically occur through the use of a rotary kiln and improve the production process by reducing metal losses and allowing the use of a wider range of scrap.

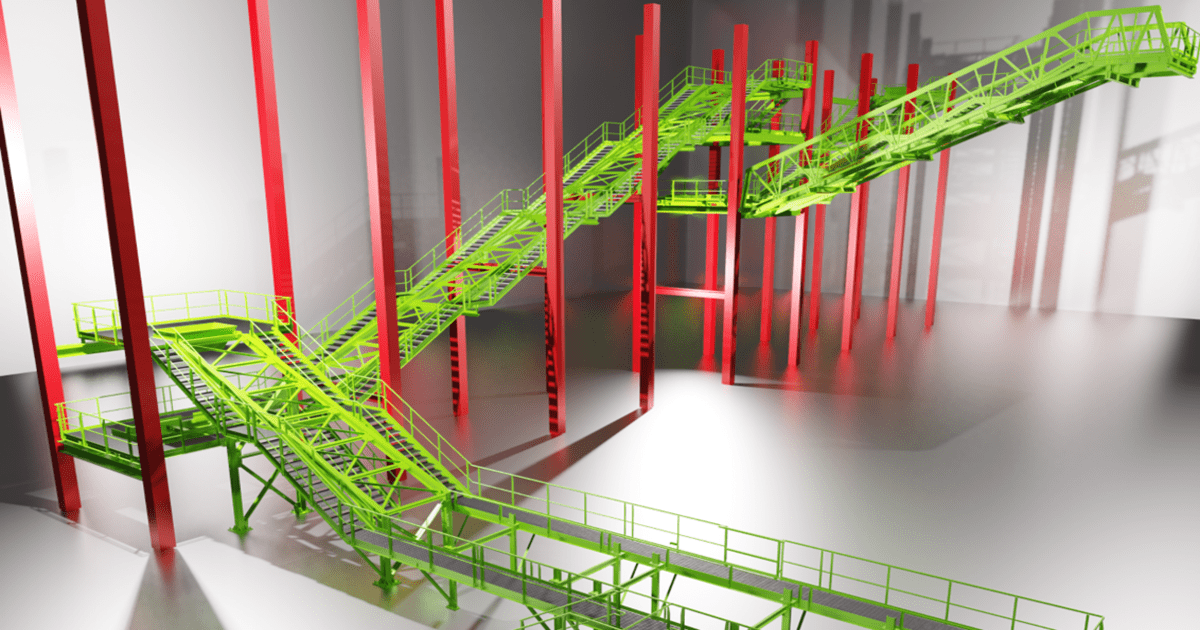

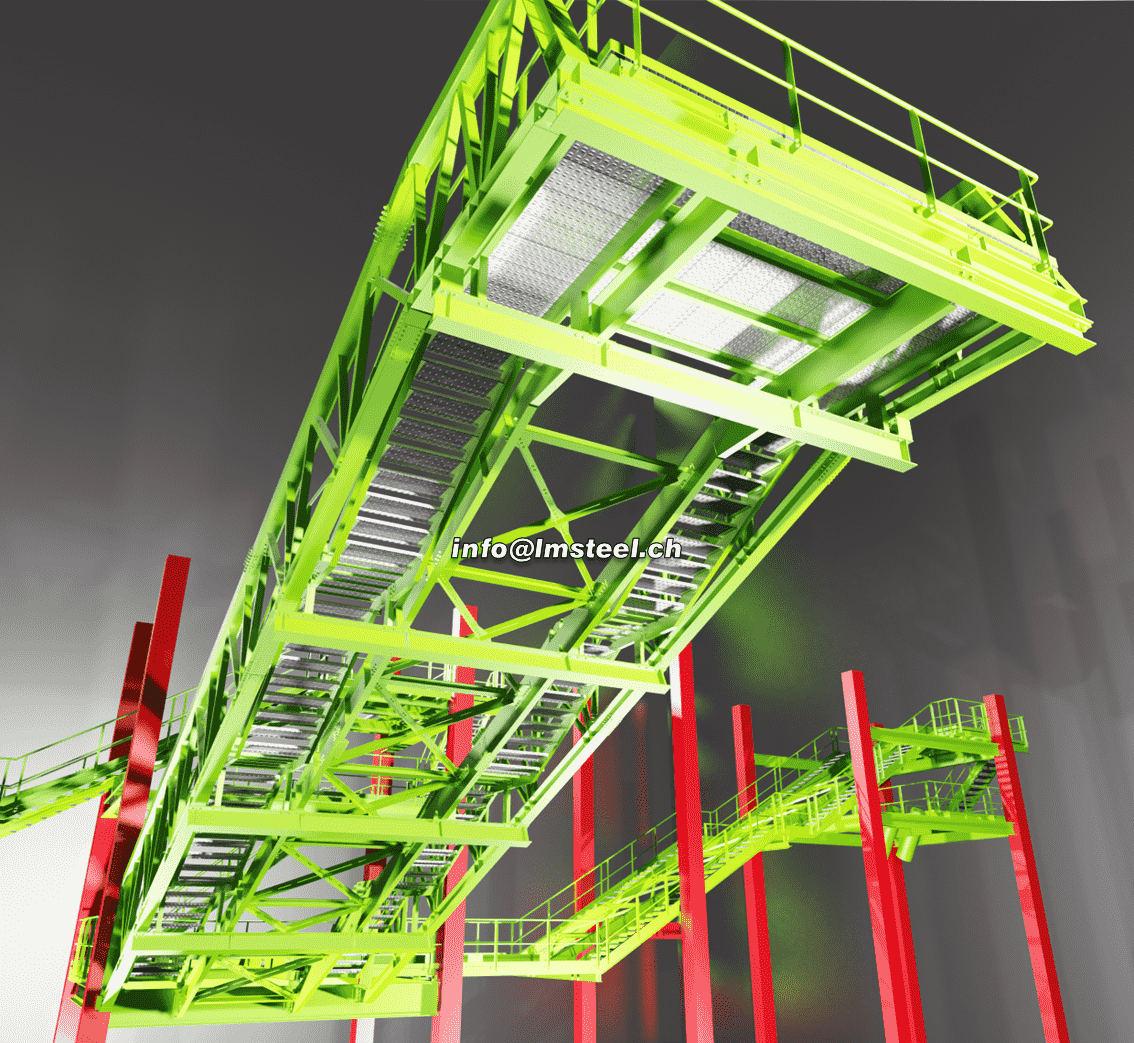

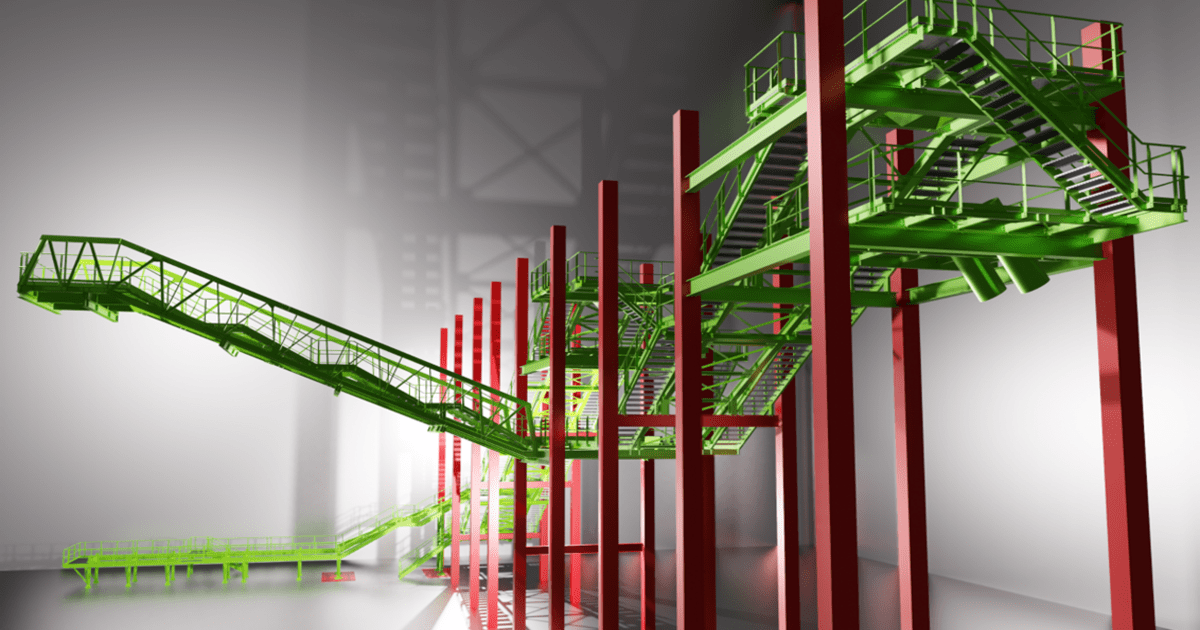

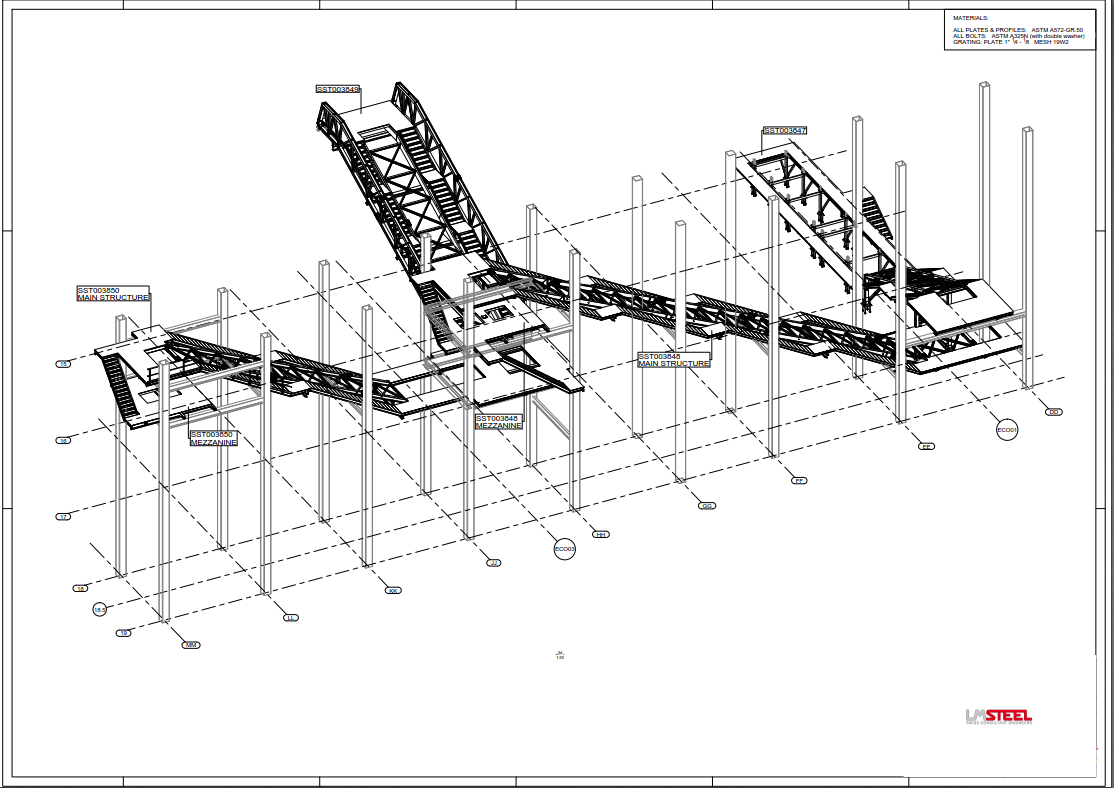

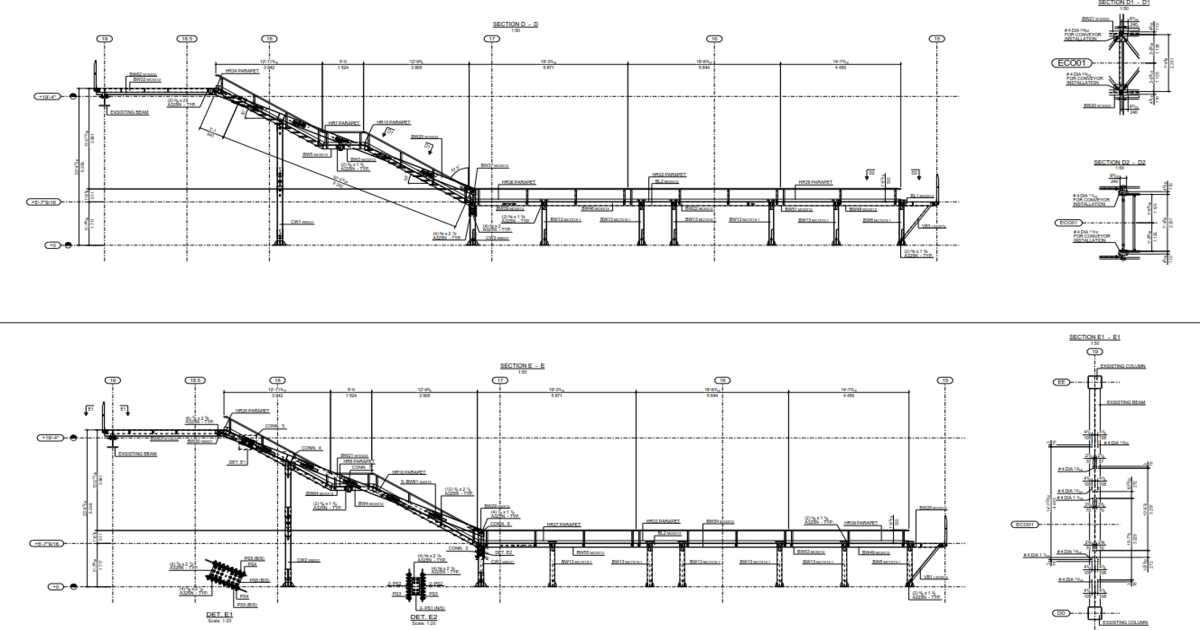

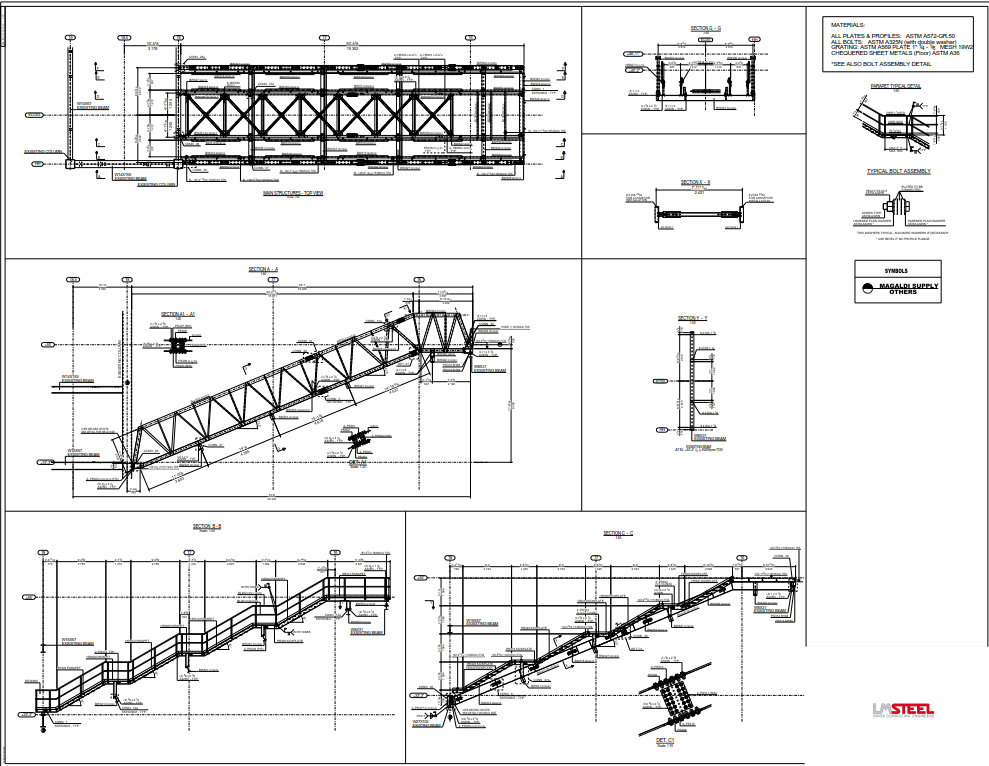

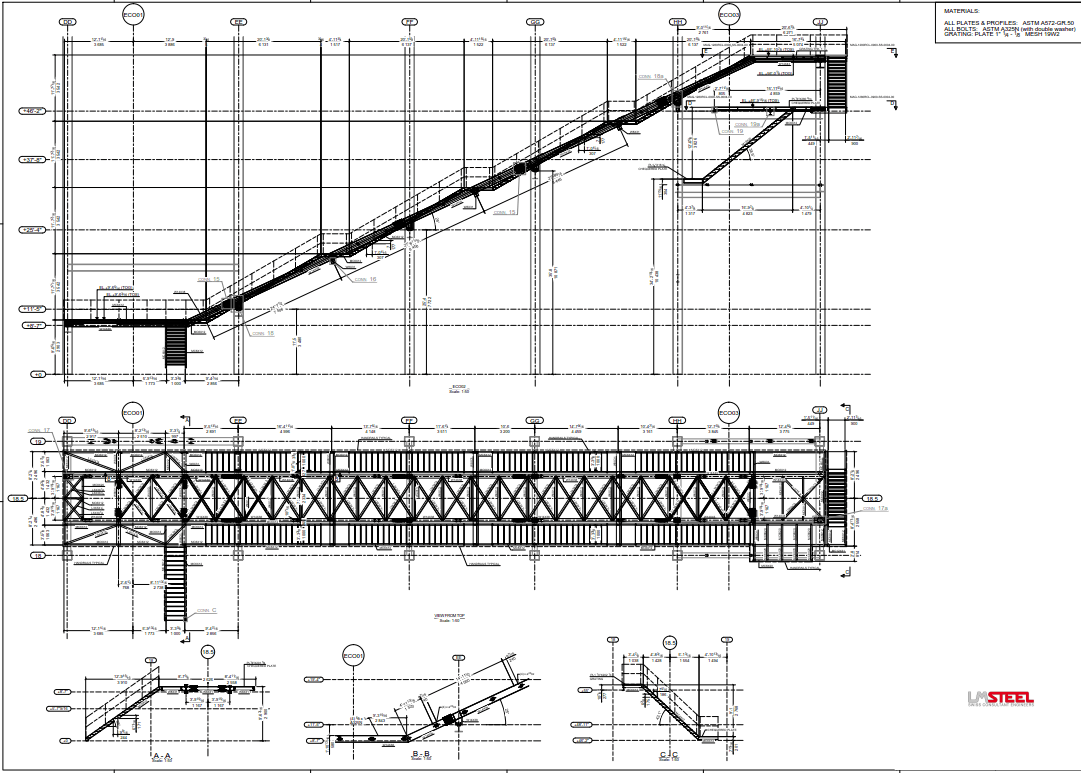

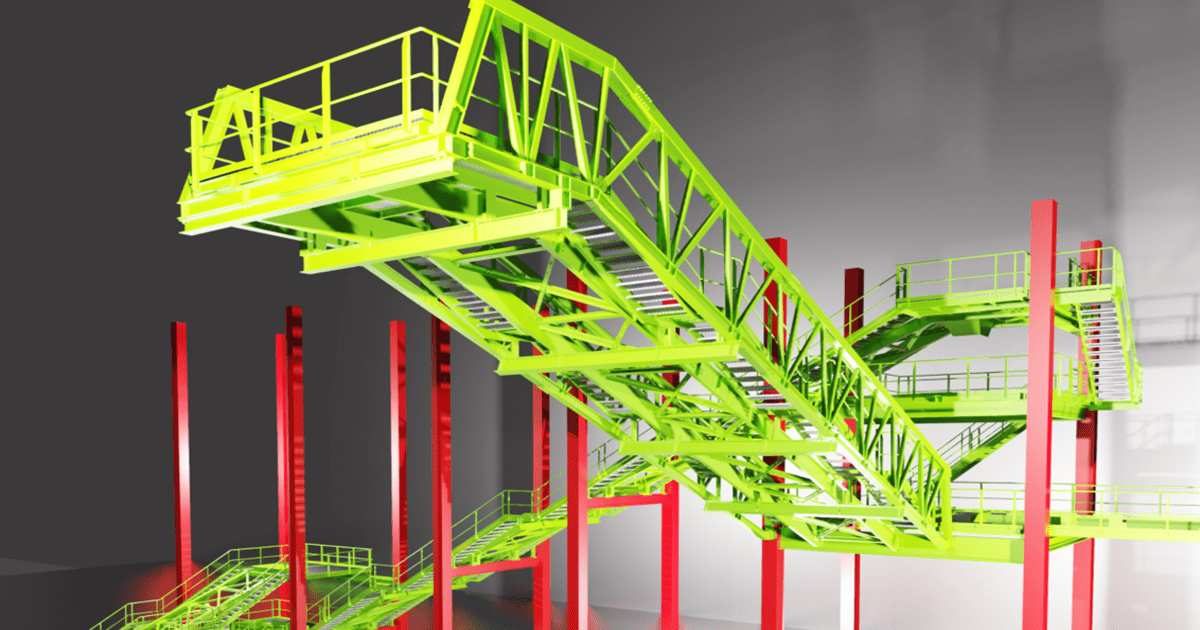

LMSTEEL Consulting sagl was in charge of the Basic and Detailed Structural Design, 3D BIM modeling "design for manufacturing" for the hopper, platform and horizontal/vertical access paths and support maintenance of the mechanical equipment in the Guthrie Production plant (KY) .

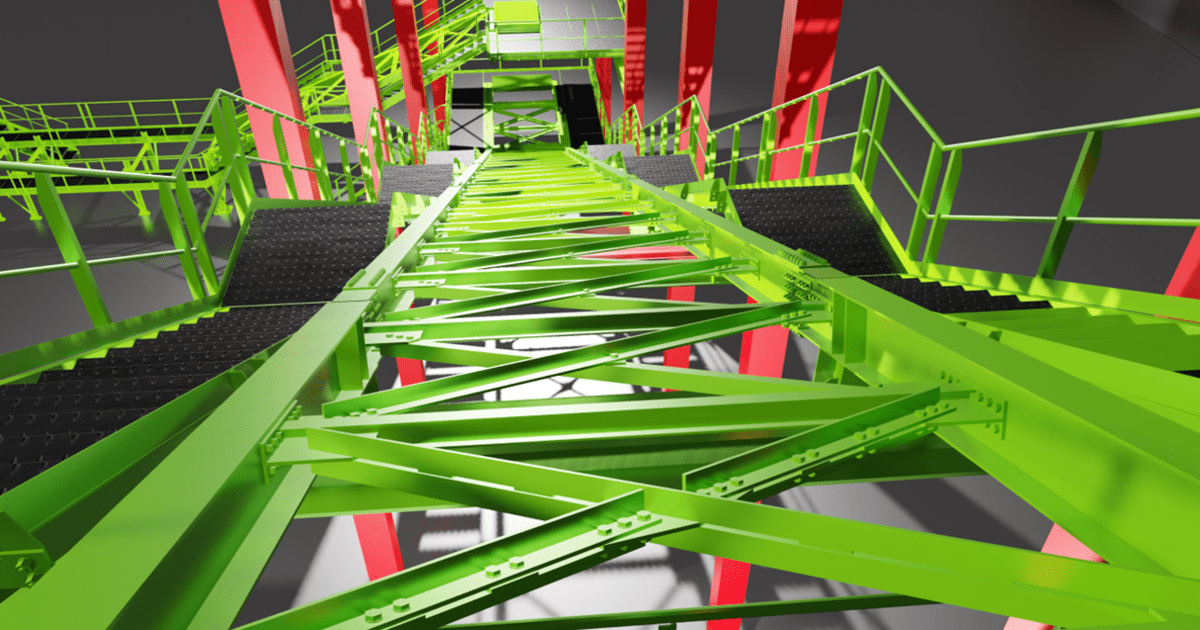

The conveyor belts are inserted in the recycling process by connecting the slagging furnace and the downstream melting furnace and are supported by a series of metal carpentry structures: transfer towers and inclined supports with spans exceeding 20 m.

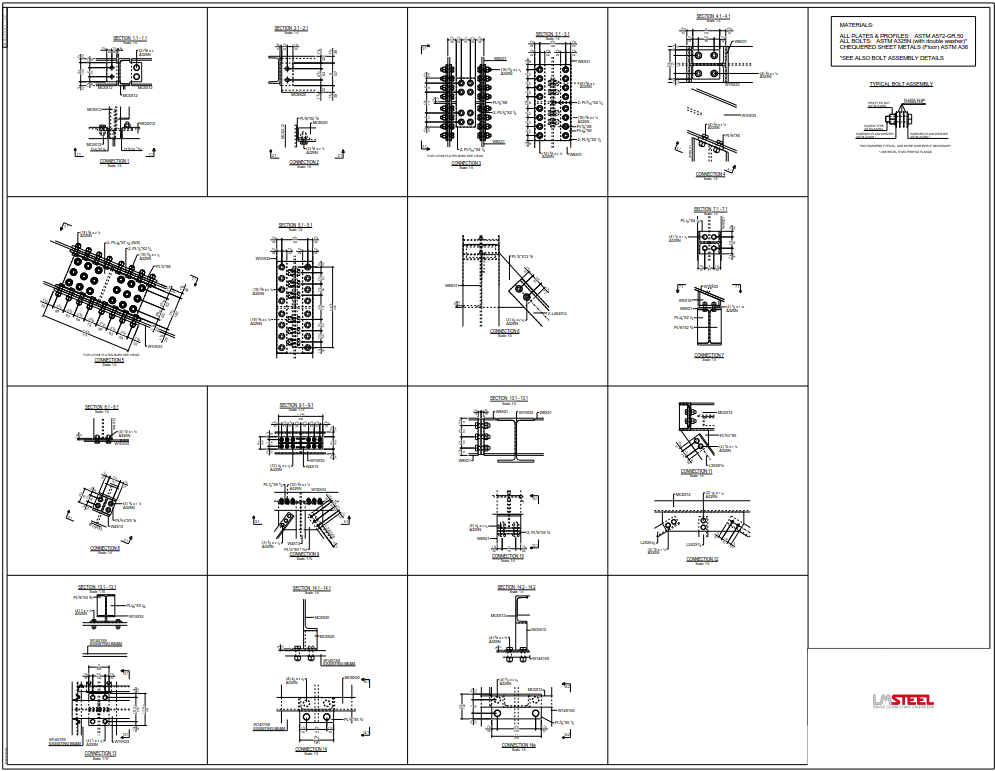

The design was validated by a local certifier taking into account the relevant American legislation (A572 Gr50 profiles according to ASTM, OSHA legislation for stairs and walkways, Kentucky Building Code)

The finite element calculation models (FEM) are developed with the Straus7 and SAP2000, and the 3D BIM geometric models with Tekla Structures up to the creation of the workshop drawings

- PLACE

- Kentucky (USA)

- YEAR

- 2023

- StatE

- Completed

- ServiCES

- Structural Design (Basic&Detail)

- "General Arrangments" drawings

- 3D BIM Modelling - Design for Manufacturing

- workshop-drawings and as-built

- FINAL CLIENT

- Confidential

- General Contractor

- Confidential

- STEEL MANUFACTURER

- Confidential

- DESIGN TEAM

- LMSteel Consulting sagl

- WEIGHT [TON]

- Confidential