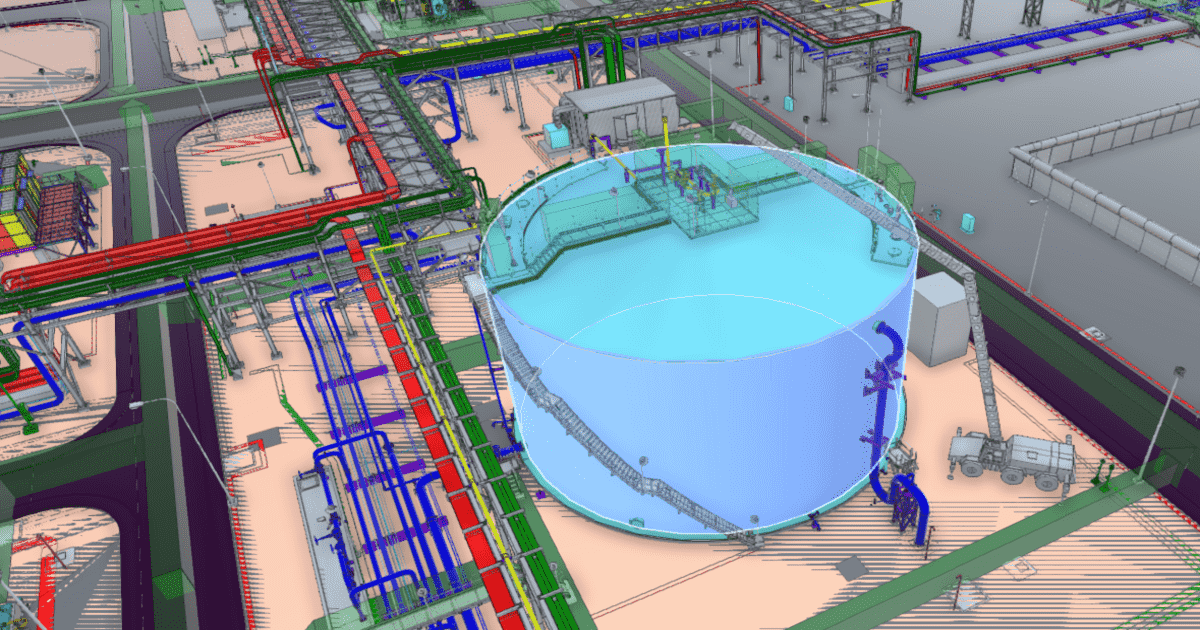

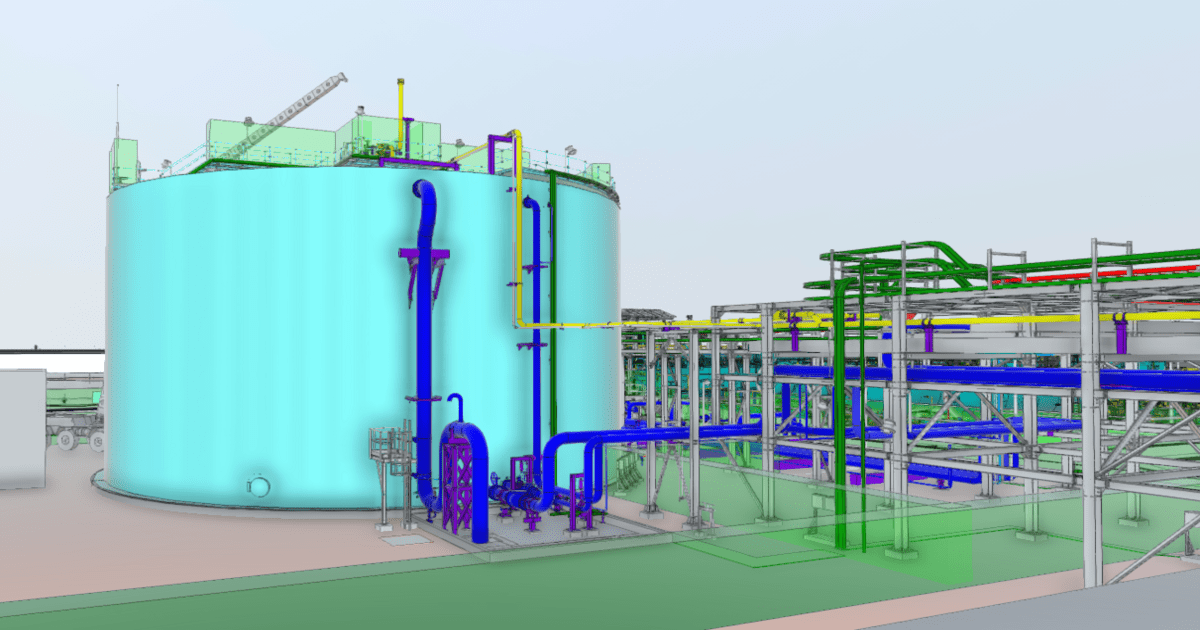

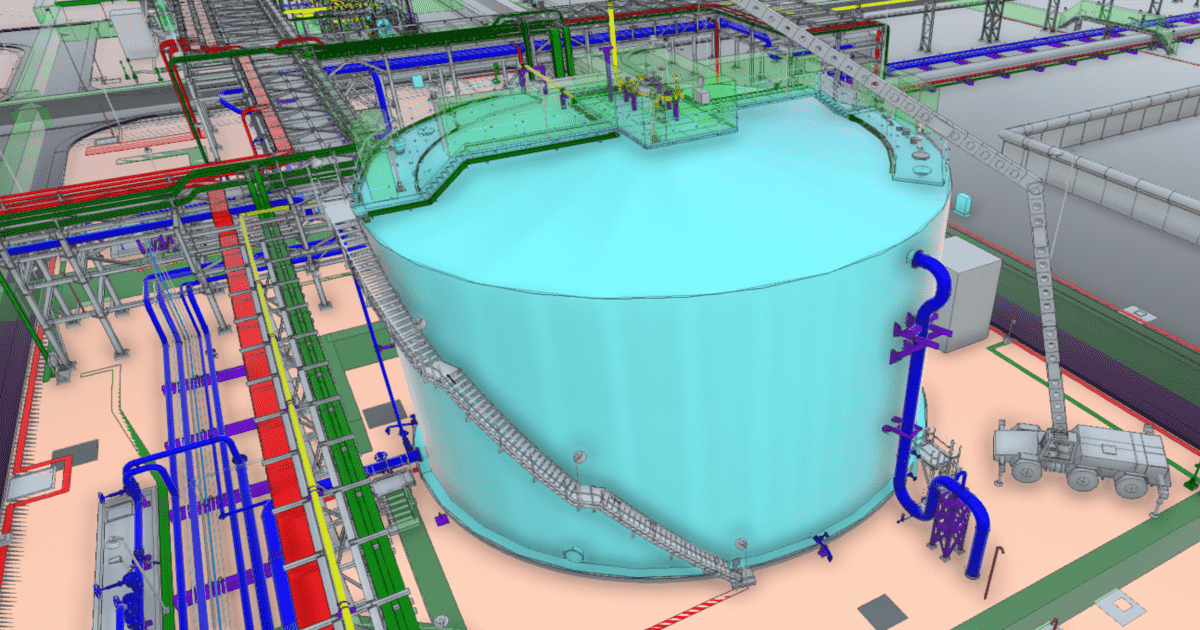

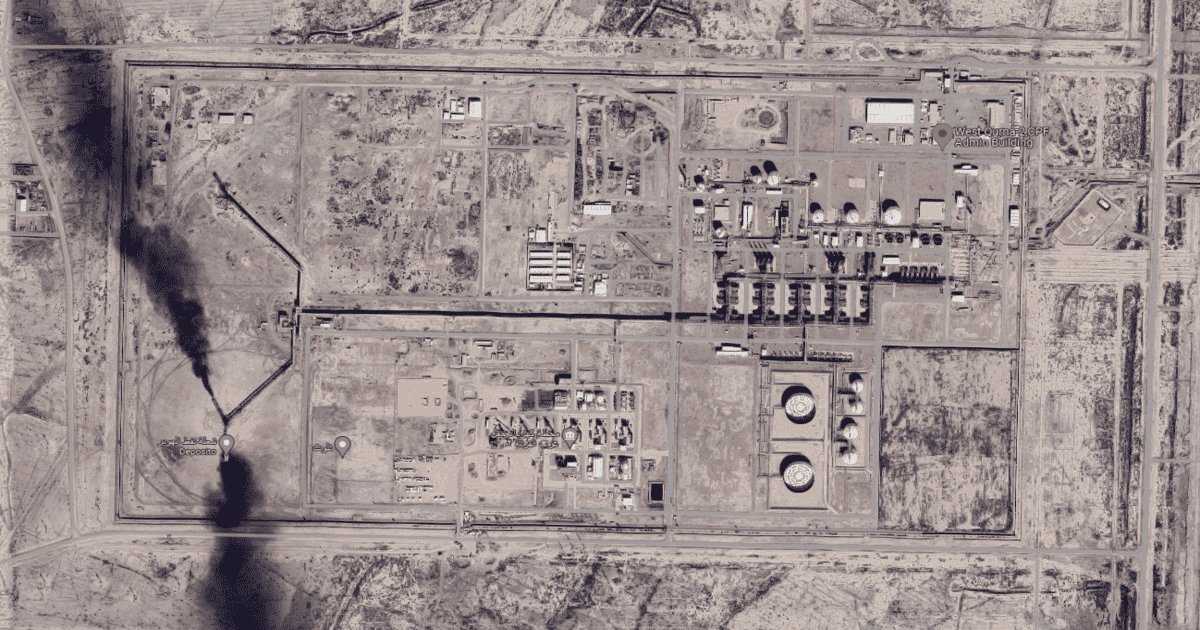

West Qurna-2 | Treated & Produced Water Tanks

The West Qurna-2 oil field is located in southern Iraq, 65 kilometers northwest of Basra, a major port city, and is one of the largest fields in the world. The field's initial recoverable reserves amount to approximately 14 billion barrels. More than 90% of the reserves are concentrated in the Mishrif and Yamama accumulations.

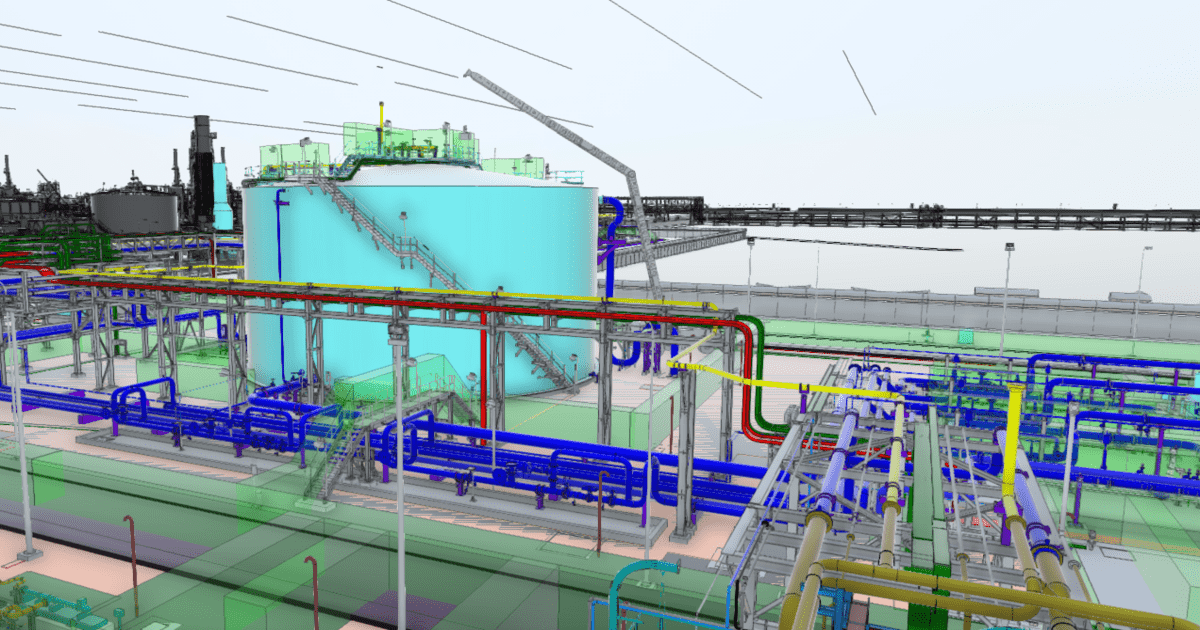

In 2009 LUKOIL Mid-East Limited (LME) was awarded a contract to develop the West Qurna-2 field with commercial oil production commencing in 2014, and is currently developing a Phase 1 extension with the expansion of produced water treatment and water injection plants (phase 2).

LMSteel Consulting provided the Structural and Mechanical Design services of the process tanks called “TREATED&PRODUCED WATER TANK” made of steel carpentry.

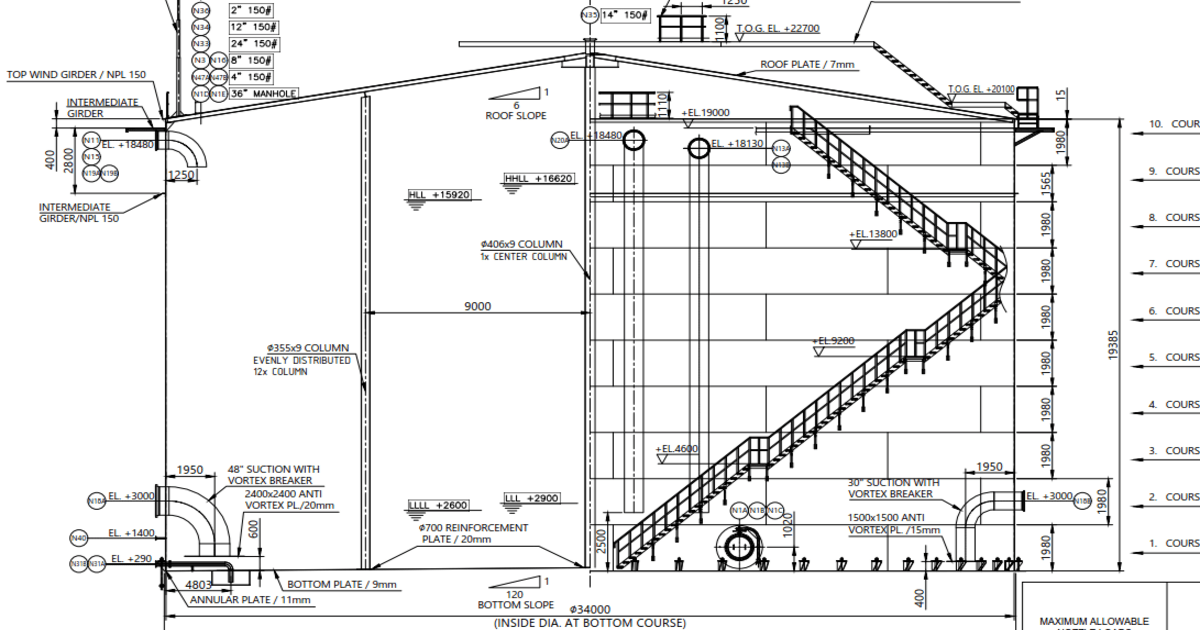

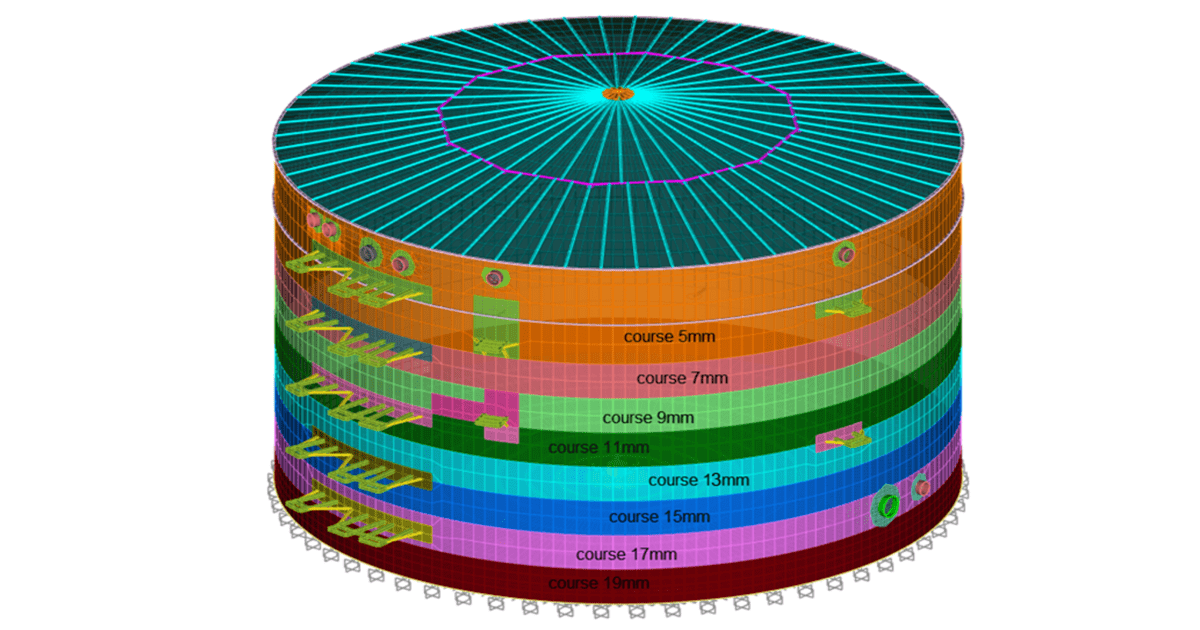

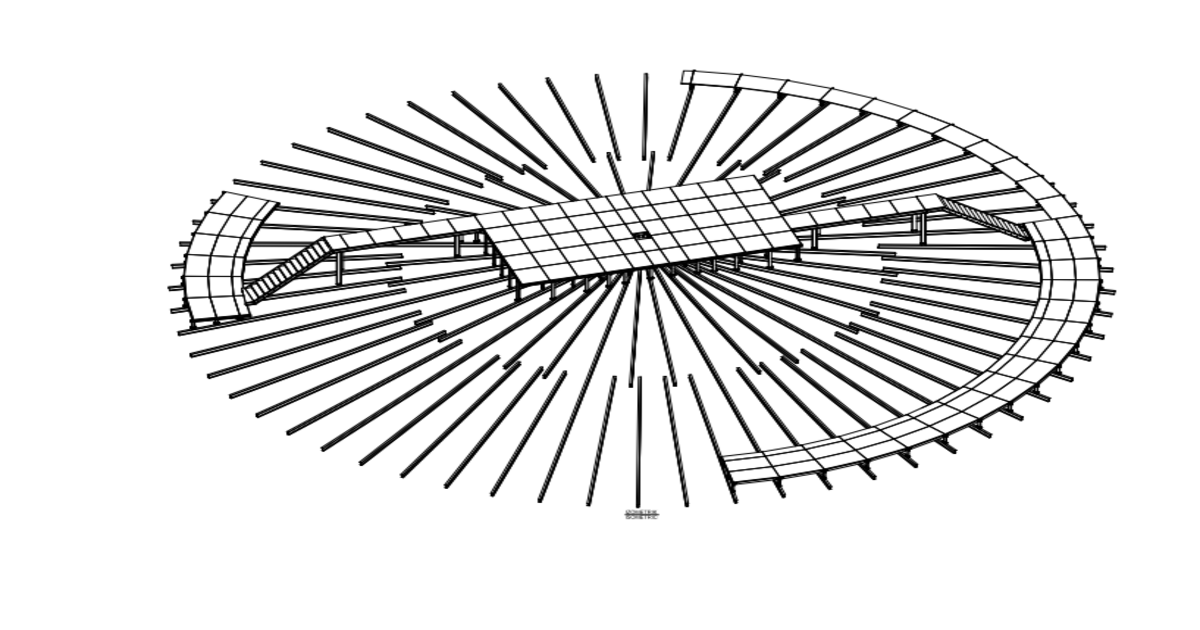

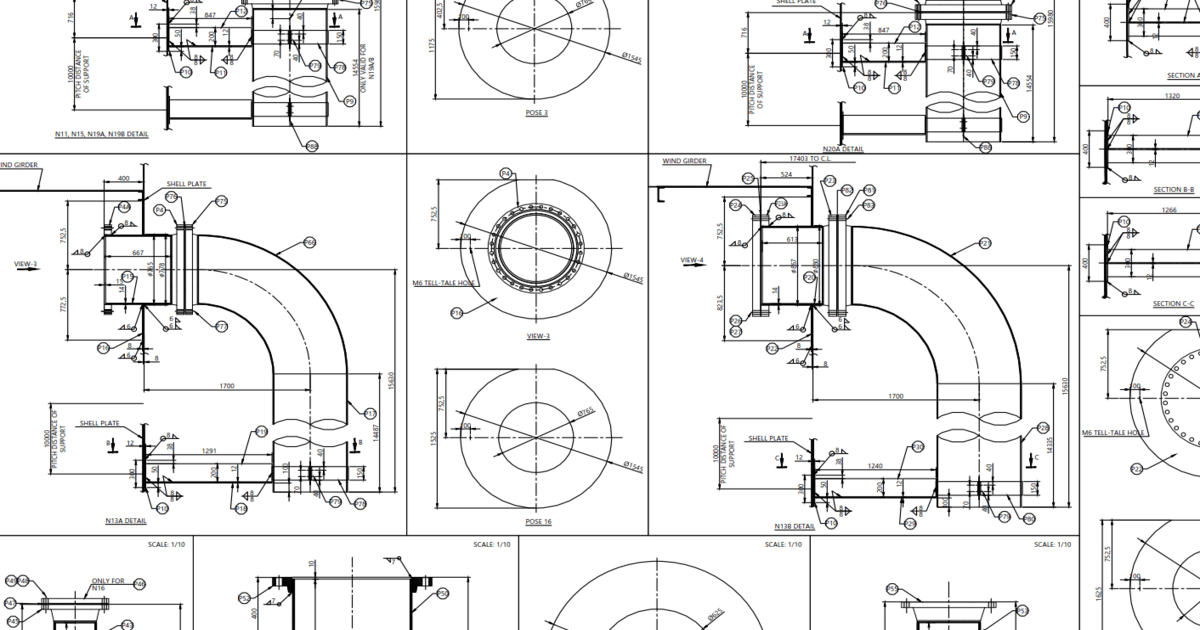

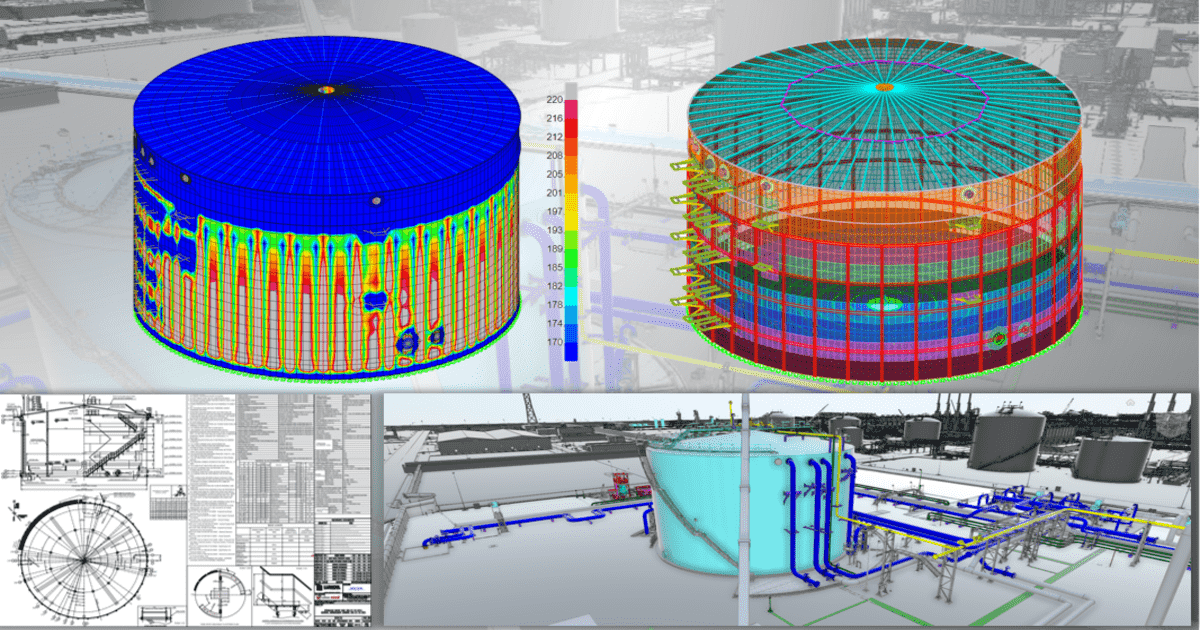

The cylindrical tanks have a diameter of 34 meters and a height of 20 meters and are composed of 10 sectors (courses) of sheet metal with a thickness varying between 22 mm at the base and 8 mm at the top. The conical structure of the roof with a 9.5° slope is composed of 7 mm thick steel sheets and radial beams, 10° inclination for the internal beams and 6° for the external beams. The entire roof is supported by a central column and 12 columns distributed along a radius of 9 m.

For the structural design, the most stringent international regulations on the subject were used, including AISC 360-16 "Specification for Structural Steel Building" and the standard guidelines API 650 "Welded Tanks for Oil Storage"

In the calculation, 3 mm of additional thickness are considered as corrosion allowance. mm. The structures are connected to the concrete foundations via M56 anchor bolts.

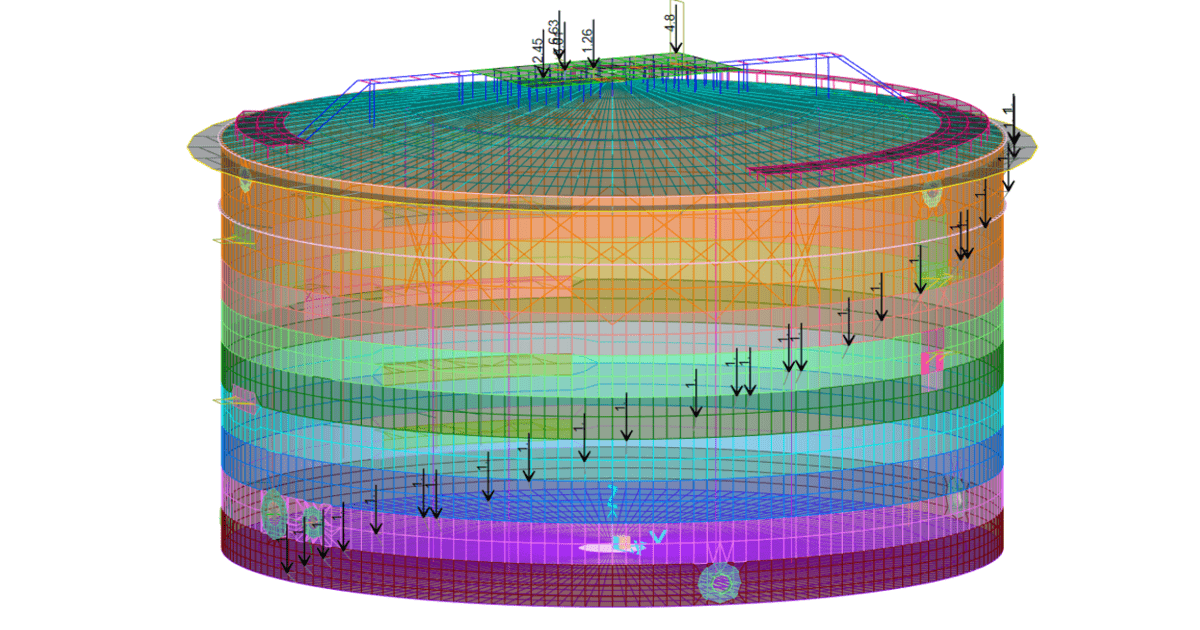

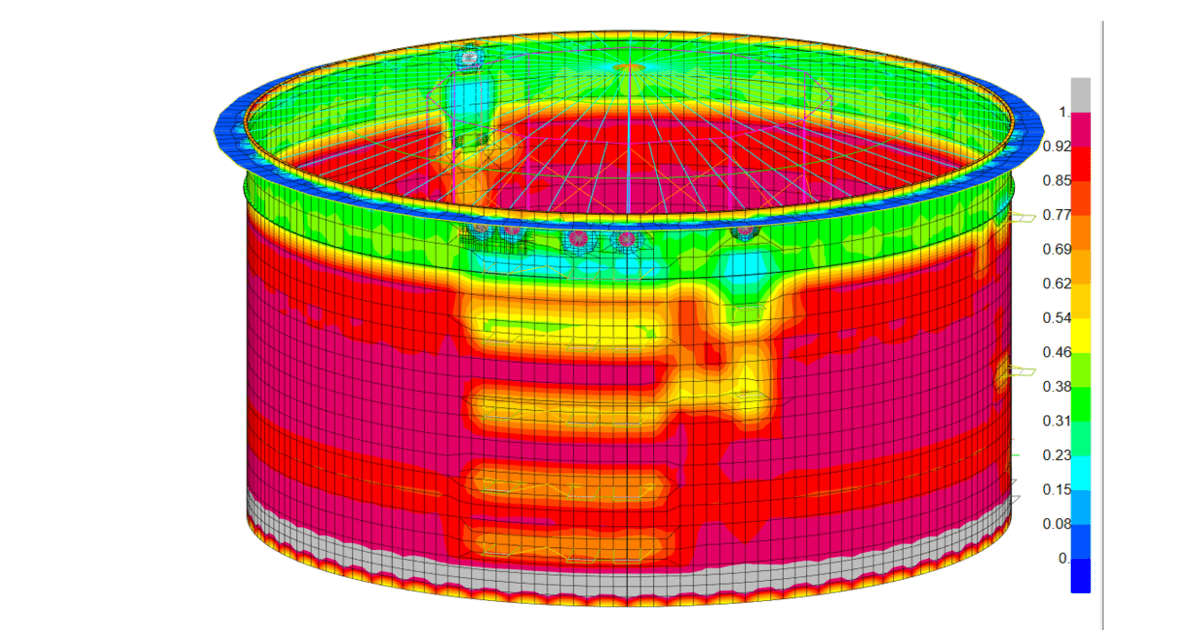

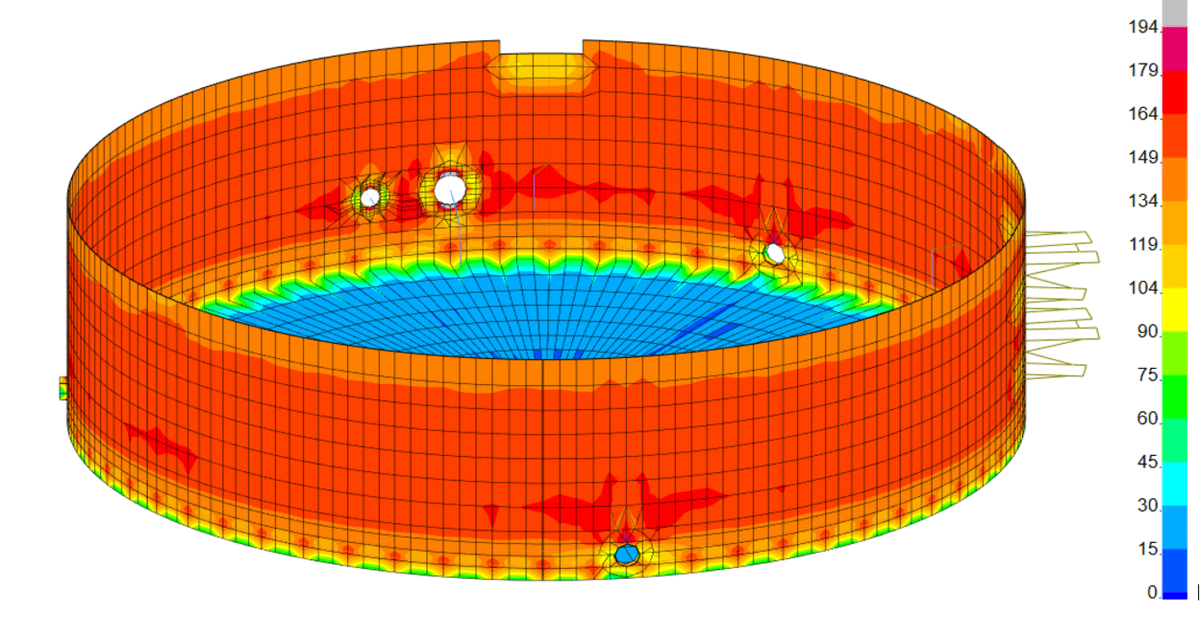

The Structural design was carried out through the development of a numerical finite element model using the SAP2000 v23.3.1 software considering the loads and combinations as per the technical specification API 650 and 8015-0151-C03-00-000-CI-SP- 00007_02. The modeling was developed with "plate" type elements with the possibility of investigating in detail the tensional state of the sheets and any local effects.

Both the environmental actions and the loads at the nozzles obtained from the "stress analysis" of the process piping lines were considered in the calculation. These actions were necessary for the study of the "piping supports" along the shell of the tanks to define the local strengthening of the ferrules.

The mechanical design was carried out using Hexagon's "TANK CX v13" software (https://hexagon.com/it/products/tank) capable of determining the necessary degrees of aeration and related adjustment pressures of the vent valves and manage all technical requirements of construction details according to API 650.

More information on the project at the following link:

https://www.lukoil.com/Business/Upstream/Overseas/WestQurna-2

- PLACE

- West Qurna-2 (Iraq)

- YEAR

- 2023

- StatE

- Completed

- ServiCES

- Structural Design (Basic&Detail)

- Mecanicha Design accordin API 650

- Maximum Allowable Loads on Nozzles

- Proposal for Courses & Columsn reinforcements

- FINAL CLIENT

- LUKOIL Mid-East Limited

- General Contractor

- SICIM spa

- STEEL MANUFACTURER

- Confidential

- STEEL STRUCTURAL DESIGN

- LMSteel Consulting sagl

- WEIGHT [TON]

- Confidential

Project Photo Gallery West Qurna-2